Genie (founded in 1966) is a hot sale brand for boom lifts in the market, Genie is an American company owned by Terex that manufactures work lifts and platforms used in construction, maintenance, warehouse stocking, and equipment installation.

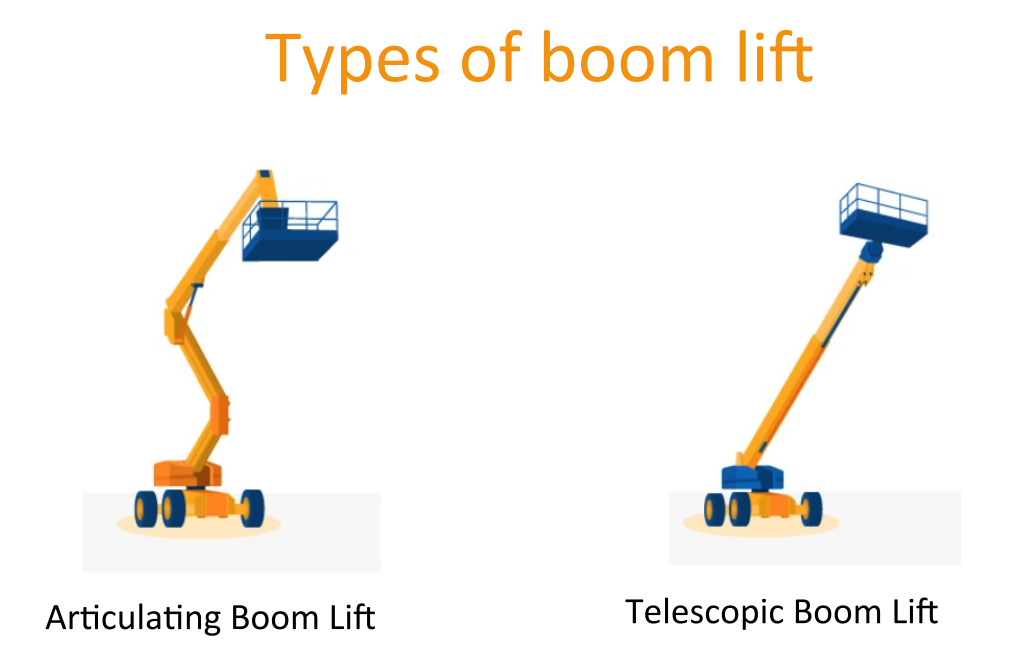

Genie boom lifts have many popular models with different feet, such as 45ft, 60ft, 80 ft, 85 ft, 125 ft telescopic and Articulating boom lifts. The popular Genie models includes Z62/40, Z-45XC, Z40/23, Z34/22, Z30/20, SX-150, S-135XC, S-60, S-80, S-85 and etc. We offer a full series of used Genie boom lifts from year 2000 to 2024.

84 ft Used Boom Lift, Genie Z80/60(2003)

84 Ft Genie Z80/60 Used Boom Lift for sale. Produced in 2003, with 8000 hours used, in good condition, certified by CE.

52 ft Used Boom Lift, Genie Z45/25JRT(2016)

52 Ft Genie Z45/25JRT Used Boom Lift for sale. Produced in 2016, with 3800 hours used, in good condition, certified by CE.

51 ft Used Boom Lift, Genie Z45/25JDC(2016)

51 Ft Genie Z45/25JDC Used Boom Lift for sale. Produced in 2016, with 3,500 hours used, in good condition, certified by CE / GB.

51 ft Used Boom Lift, Genie Z45/25JDC(2016)

51 Ft Genie Z45/25JDC Used Boom Lift for sale. Produced in 2016, with 3000 hours used, in good condition, certified by CE / GB.

51 ft Used Boom Lift, Genie Z45/25JDC(2016)

51 Ft Genie Z45/25JDC Used Boom Lift for sale. Produced in 2016, with 1400 hours used, in good condition, certified by CE.

186 ft Used Boom Lift, Genie SX-180(2014)

186 Ft Genie SX-180 Used Boom Lift for sale. Produced in 2014, with 2000 hours used, in good condition, certified by ANSI.

111 ft Used Boom Lift, Genie S105(2017)

111 Ft Genie S105 Used Boom Lift for sale. Produced in 2017, with 3600 hours used, in good condition, certified by CE.

91 ft Used Boom Lift, Genie S85(2019)

91 Ft Genie S85 Used Boom Lift for sale. Produced in 2019, with 3800 hours used, in good condition, certified by CE / GB.

91 ft Used Boom Lift, Genie S85(2018)

91 Ft Genie S85 Used Boom Lift for sale. Produced in 2018, with 4350 hours used, in good condition, certified by CE / GB.

51 Ft Used Boom Lift, Genie Z45/25JDC(2019)

Genie Z45/25JDC Boom Lift (2019) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model Z45/25JDC Condition Used with well functional. Year of Make 2019 Hours Meters 1,900 Serial NO….

51 Ft Used Boom Lift, Genie Z45/25JDC(2018)

Genie Z45/25JDC Boom Lift (2018) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model Z45/25JDC Condition Used with well functional. Year of Make 2018 Hours Meters 2,300 Serial NO….

91 Ft Used Boom Lift, Genie S85(2017)

Genie S85 Boom Lift (2017) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S85 Condition Used with well functional. Year of Make 2017 Hours Meters 5,800 Serial NO….

91 Ft Used Boom Lift, Genie S85(2018)

Genie S85 Boom Lift (2018) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S85 Condition Used with well functional. Year of Make 2017 Hours Meters 5,200 Serial NO….

71 Ft Used Boom Lift, Genie S65(2017)

Genie S65 Boom Lift (2017) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S65 Condition Used with well functional. Year of Make 2017 Hours Meters 4800 Serial NO….

71 Ft Used Boom Lift, Genie S65(2016)

Genie S65 Boom Lift (2016) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S65 Condition Used with well functional. Year of Make 2016 Hours Meters 5200 Serial NO….

66 Ft Used Boom Lift, Genie S60(2016)

Genie S60 Boom Lift (2016) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S60 Condition Used with well functional. Year of Make 2016 Hours Meters 3900 Serial NO….

66 Ft Used Boom Lift, Genie S60(2017)

Genie S60 Boom Lift (2017) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S60 Condition Used with well functional. Year of Make 2017 Hours Meters 4800 Serial NO….

66 Ft Used Boom Lift, Genie S60(2015)

Genie S60 Boom Lift (2015) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S60 Condition Used with well functional. Year of Make 2015 Hours Meters 5800 Serial NO….

66 Ft Used Boom Lift, Genie S60(2016)

Genie S60 Boom Lift (2016) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S60 Condition Used with well functional. Year of Make 2016 Hours Meters 5400 Serial NO….

66 Ft Used Boom Lift, Genie S60(2015)

Genie S60 Boom Lift (2015) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S60 Condition Used with well functional. Year of Make 2015 Hours Meters 5700 Serial NO….

65 Ft Used Boom Lift, Genie Z60/37FE(2021)

Genie Z60/37FE Boom Lift (2021) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model Z60/37FE Condition Used with well conditions Year of Make 2021 Hours Meters 600 Serial NO….

66 Ft Used Boom Lift, Genie Z60/34(2012)

Genie Z60/34 Boom Lift (2012) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model Z60/34 Condition Used with well conditions Year of Make 2012 Hours Meters 2,000 Serial NO….

57 Ft Used Boom Lift, Genie Z51/30JRT(2008)

Genie Z51/30JRT Boom Lift (2008) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model Z51/30JRT Condition Used with well conditions Year of Make 2008 Hours Meters 2,980 Serial NO….

38 Ft Used Boom Lift, Genie Z33/18(2022)

Genie Z33/18 Boom Lift (2022) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model Z33/18 Condition Used with well conditions Year of Make 2022 Hours Meters 200 Serial NO….

126 Ft Used Boom Lift, Genie S120(2015)

Genie S120 Boom Lift (2015) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S120 Condition Used with well conditions Year of Make 2015 Hours Meters 3,000 Serial NO….

106 Ft Used Boom Lift, Genie S100(2013)

Genie S100 Boom Lift (2013) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S100 Condition Used with well conditions Year of Make 2013 Hours Meters 1,000 Serial NO….

46 Ft Used Boom Lift, Genie S40(2015)

Genie S40 Boom Lift (2015) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S40 Condition Used with well conditions Year of Make 2015 Hours Meters 2,000 Serial NO….

60 Ft Used Boom Lift, JLG E600JP (2014)

JLG E600JP boom lift (2014) | Used boom lift For Sale This used JLG E600JP boom lift was manufactured in 2014 and certified by ANSI GB. It has a working…

29 Ft Used Boom Lift, JLG E300AJP (2008)

JLG E300AJP boom lift (2008) | Used boom lift For Sale This used JLG E300AJP boom lift was manufactured in 2014 and certified by ANSI GB. It has a working…

185 Ft Used Boom Lift, JLG 1850SJ(2014)

JLG 1850SJ boom lift (2014) | Used boom lift For Sale This used JLG 1850SJ boom lift was manufactured in 2014 and certified by ANSI GB. It has a working…

46 Ft Used Boom Lift, JLG 460SJ (2015)

JLG 460SJ boom lift (2015) | Used boom lift For Sale This used JLG 460SJ boom lift was manufactured in 2015 and certified by ANSI GB. It has a working…

40 Ft Used Boom Lift, JLG 400S (2019)

JLG 400S boom lift (2019) | Used boom lift For Sale This used JLG 400S boom lift was manufactured in 2019 and certified by ANSI GB. It has a working platform…

33 Ft Used Boom Lift, JLG 340AJ (2014)

JLG 340AJ boom lift (2014) | Used boom lift For Sale This used JLG 340AJ boom lift was manufactured in 2014 and certified by ANSI GB. It has a working…

67 Ft Used Boom Lift, Genie Z-62/40(2013)

Genie Z-62/40 Boom Lift (2013) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model Z-62/40 Condition Used with well conditions Year of Make 2017 Hours Meters 1500 Serial NO….

51 Ft Used Boom Lift, Genie Z-45 XC(2013)

Genie Z-45 XC Boom Lift (2013) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model Z-45 XC Condition Used with well conditions Year of Make 2023 Hours Meters 190…

46 Ft Used Boom Lift, Genie Z-40/23 N(2013)

Genie Z-40/23 N Boom Lift (2013) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model Z-40/23 N Condition Used with well conditions Year of Make 2013 Hours Meters 890…

40 Ft Used Boom Lift, Genie Z-34/22 N(2016)

Genie Z-34/22 N Boom Lift (2016) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model Z-34/22 N Condition Used with well conditions Year of Make 2014 Hours Meters 950…

36 Ft Used Boom Lift, Genie Z-30/20 N(2016)

Genie Z-30/20 N Boom Lift (2016) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model Z-30/20 N Condition Used with well conditions Year of Make 2017 Hours Meters 350…

158 Ft Used Boom Lift, Genie SX-150(2015)

Genie SX-150 Boom Lift (2015) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model SX-150 Condition Used with well conditions Year of Make 2015 Hours Meters 3500 Serial NO….

141 Ft Used Boom Lift, Genie S-135 XC(2017)

Genie S-135 XC Boom Lift (2017) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S-135 XC Condition Used with well conditions Year of Make 2017 Hours Meters 500 Serial…

86 Ft Used Boom Lift, Genie S-80(2012)

Genie S-80 Boom Lift (2012) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S-80 Condition Used with well conditions Year of Make 2012 Hours Meters 4050 Serial NO….

66 Ft Used Boom Lift, Genie S-60(2016)

Genie S-60 Boom Lift (2016) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S-60 Condition Used with well conditions Year of Make 2016 Hours Meters 5400 Serial NO….

50 Ft Used Boom Lift, Genie S-45 XC(2023)

Genie S-45 XC Boom Lift (2023) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S-45 XC Condition Used with well conditions Year of Make 2023 Hours Meters 500 Serial…

135 Ft Used Boom Lift, JLG 1500AJP (2019)

JLG 1500AJP boom lift (2019) | Used boom lift For Sale This used JLG 1500AJP boom lift was manufactured in 2019 and certified by ANSI GB. It has a working…

135 Ft Used Boom Lift, JLG 1350SJP (2013)

JLG 1350SJP boom lift (2013) | Used boom lift For Sale This used JLG 1350SJP boom lift was manufactured in 2013 and certified by ANSI GB. It has a working…

120 Ft Used Boom Lift, JLG 1200SJP (2013)

JLG 1200SJP boom lift (2013) | Used boom lift For Sale This used JLG 1200SJP boom lift was manufactured in 2013 and certified by ANSI GB. It has a working…

60 Ft Used Boom Lift, JLG 600AJ (2014)

JLG 600AJ boom lift (2014) | Used boom lift For Sale This used JLG 600AJ boom lift was manufactured in 2014 and certified by ANSI GB. It has a working…

45 Ft Used Boom Lift, JLG E450AJ (2023)

JLG E450AJ boom lift (2023) | Used boom lift For Sale This used JLG E450AJ boom lift was manufactured in 2023 and certified by ANSI GB. It has a working…

135 ft Used Boom Lift, JLG 1350SJ (2015)

JLG 1350SJ Boom Lift (2015) | Used Boom Lift For Sale Unit Specifications Manufacturer JLG Model 1350SJ Condition Used Year of Make 2015 Hours Meters 3,000 Serial NO. To be…

135 ft Used Boom Lift, JLG 1350SJ (2012)

JLG 1350SJ Boom Lift (2012) | Used Boom Lift For Sale Unit Specifications Manufacturer JLG Model 1350SJ Condition Used Year of Make 2012 Hours Meters 5,500 Serial NO. To be…

125 ft Used Boom Lift, JLG 1250AJP (2011)

JLG 1250AJP boom lift (2011) | Used boom lift For Sale This used JLG 1250AJP boom lift was manufactured in 2011 and certified by ANSI GB. It has a working…

86 ft Used Boom Lift, 860SJ (2022)

JLG 860SJ boom lift (2022) | Used boom lift For Sale This used JLG 860SJ boom lift was manufactured in 2022 and certified by ANSI GB. It has a working…

86 ft Used Boom Lift, JLG 860SJ (2014)

JLG 860SJ boom lift (2014) | Used boom lift For Sale This used JLG 860SJ boom lift was manufactured in 2014 and certified by ANSI GB. It has a working…

86 ft Used Boom Lift, JLG 800AJ (2014)

JLG 800AJ boom lift (2014) | Used boom lift For Sale This used JLG 800AJ boom lift was manufactured in 2014 and certified by ANSI. It has a working platform…

72 ft Used Boom Lift, JLG 660SJ (2011)

JLG 660SJ boom lift (2011) | Used boom lift For Sale This used JLG 660SJ boom lift was manufactured in 2011 and certified by ANSI GB. It has a working…

186 ft Used Boom Lift, Genie SX-180 (2014)

Genie SX-180 Boom Lift (2014) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model SX-180 Condition Used Year of Make 2014 Hours Meters 2,000 Serial NO. To be…

66 ft Used Boom Lift, JLG EC600SJP (2021)

JLG EC600SJP boom lift (2021) | Used boom lift For Sale This used JLG EC600SJP boom lift was manufactured in 2021 and certified by ANSI. It has a working platform…

125 ft Used Boom Lift, JLG 1250AJP (2012)

JLG 1250AJP boom lift (2012) | Used boom lift For Sale This used JLG 1250AJP boom lift was manufactured in 2012 and certified by ANSI GB. It has a working…

86 ft Used Boom Lift, JLG 800S (2011)

JLG 800S boom lift (2011) | Used boom lift For Sale This used JLG 800S boom lift was manufactured in 2014 and certified by ANSI GB. It has a working…

86 ft Used Boom Lift, JLG 800AJ (2011)

JLG 800AJ boom lift (2011) | Used boom lift For Sale This used JLG 800AJ boom lift was manufactured in 2014 and certified by ANSI. It has a working platform…

141 ft Used Boom Lift, Genie Z135/70 (2010)

Genie Z135/70 Boom Lift (2010) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model Z135/70 Condition Used (90% Refurbished, New Wheel & New Battery) Year of Make 2010 Hours Meters…

84 ft Used Boom Lift, Genie Z80/60 (2003)

Genie Z80/60 Boom Lift (2003) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model Z80/60 Condition Used (90% Refurbished, New Wheel & New Battery) Year of Make 2003 Hours Meters…

51 ft Used Boom Lift, Genie Z45/25JDC (2016)

Genie Z45/25JDC Boom Lift (2016) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model Z45/25JDC Condition Used (90% Refurbished, New Wheel & New Battery) Year of Make 2016 Hours Meters…

186 ft Used Boom Lift, Genie SX-180 XC (2015)

Genie SX-180 XC Boom Lift (2015) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model SX-180 Condition Used Year of Make 2015 Hours Meters 1800 Serial NO. To be subject…

131 ft Used Boom Lift, Genie SX-125 XC (2019)

Genie SX-125 XC Boom Lift (2019) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model SX-125 XC Condition Used Year of Make 2019 Hours Meters 3200 Serial NO….

80 ft Used Boom Lift, Genie S105 (2017)

Genie S105 Boom Lift (2017) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S105 Condition Used Year of Make 2017 Hours Meters 3600 Serial NO. To be…

91 ft Used Boom Lift, Genie S85 (2017)

Genie S85 Boom Lift (2017) | Used Boom Lift For Sale | Rental Unit Specifications Manufacturer Genie Model S85 Condition Used Year of Make 2017 Hours Meters 4500 Serial NO….

71 ft Used Boom Lift, Genie S65 (2017)

Genie S65 Boom Lift (2017) | Used Boom Lift For Sale Unit Specifications Manufacturer Genie Model S65 Condition Used (90% Refurbished, New Wheel & New Battery) Year of Make 2017…

All Parts

FAQs

Related Blog

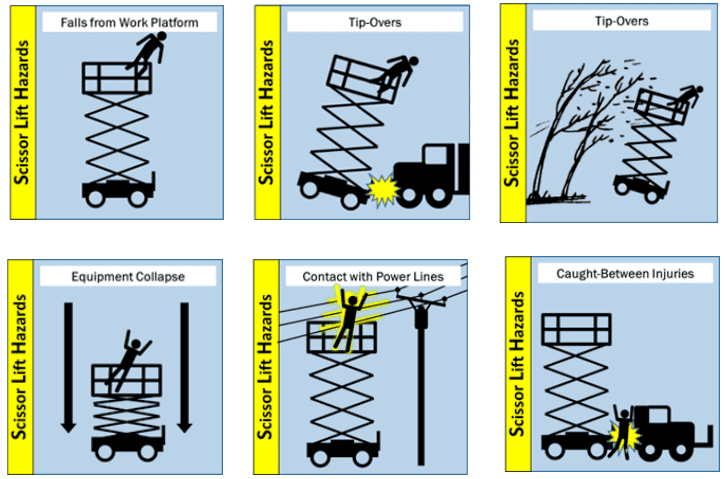

Is Fall Protection Required On Scissor Lift?

Is Fall Protection Required On Scissor Lift? Scissor lifts have a wide range of applications in fields such as construction, logistics, and warehousing. It provides a convenient and efficient solution for workers to transport and lift heavy objects, saving time and…

How Wide Is Scissor Lift?

How wide is a scissor lift? The width of scissor lifts varies depending on factors such as model, purpose, and design. Small scissor lift Small models for indoor use This type of scissor lift is mainly used for low altitude…

Does OSHA Require Harness In Scissor Lift?

Does OSHA require a harness in a scissor lift? OSHA, also known as the Occupational Safety and Health Administration in the United States, plays a crucial role in ensuring workplace safety. As a commonly used high-altitude operation equipment, scissor lifts…

How To Release Brakes On Scissor Lift?

How to release brakes on scissor lift? Scissor lift is a high safety equipment during using. The way the scissor lift releases the brake may vary depending on the model and manufacturer. Here are some common steps: Check the equipment…

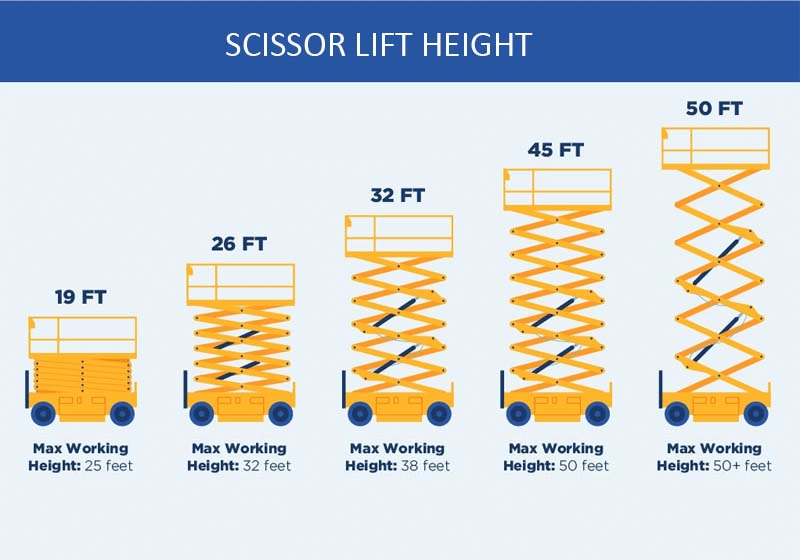

How High Can Scissor Lift Go?

How high can a scissor lift go? As an important aerial work platform, scissor lifts have various types, each with its unique features and applications. There are various models of scissor lifts with different lifting ranges. Fixed scissor lift: The lifting height can range…

How To Transport Scissor Lift?

How to transport a scissor lift? Scissor lifts can quickly transport goods from one place to another, reducing the time and cost of manual. Especially in warehouses, production lines, and other places, scissor lifts can easily transport heavy objects, providing…

How Large Is a 19ft JLG Scissor Lift

How large is a 19ft JLG scissor lift The 19ft JLG scissor lift is the JLG model 1932. The JLG 1932 scissor lift provides efficient and safe solutions for the high-altitude work needs of many industries. The JLG 1932 scissor…

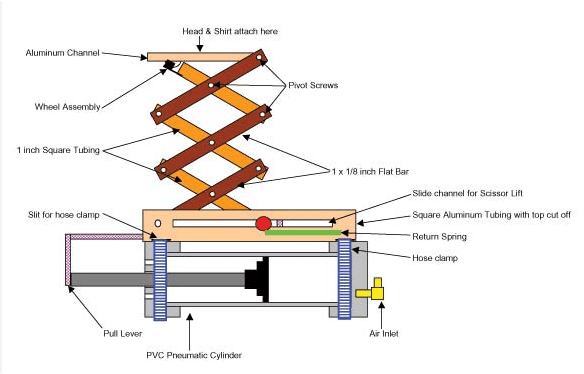

How Does Scissor Lift Work?

How does scissor lift work? Scissor lift is a device like its name which uses a “scissor” design structure to achieve lifting and lowering functions, and is currently widely used for indoor and outdoor jobs. It is small in size and easy…

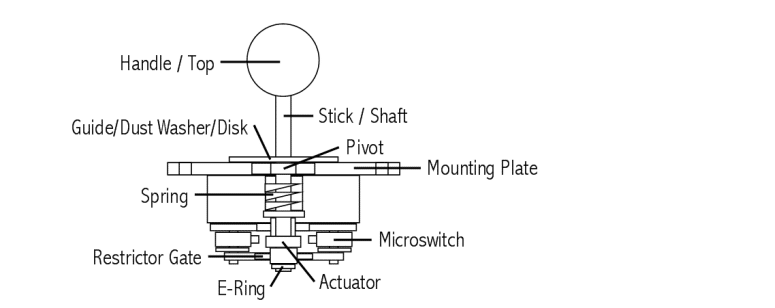

The Role of Joysticks in Scissor Lifts and Boom Lifts: A Comprehensive Guide

Understanding the Role of Joysticks in Scissor Lifts and Boom Lifts What Is A Joystick? A joystick on a scissor lift/boom lift is a physical input device which can convert the movement of a plastic rod into electronic information that can be…

What Is The Scissor Lift Toggle Switch?

What Is The Scissor Lift Toggle Switch? Quick Summary Of Scissor Lift Toggle Switch Scissor lift toggle switches are a common type of switch used in equipment. From an exterior perspective, scissor lift toggle switches typically feature a compact casing…

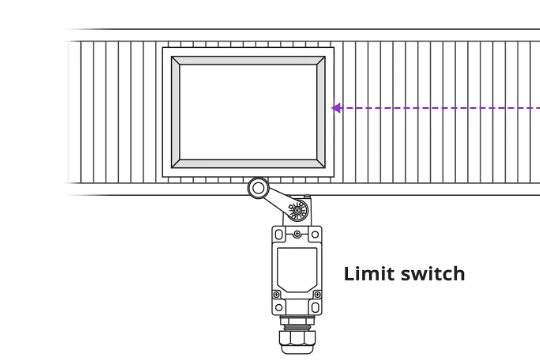

What Is a Limit Switch On lifts & How Does it Works?

What Is a Limit Switch On lifts & How Does it Works? Definition Of Limit Switch For scissor lifts and boom lifts, the limit switch plays an important role in controlling the working in a limited position which ensures safety…

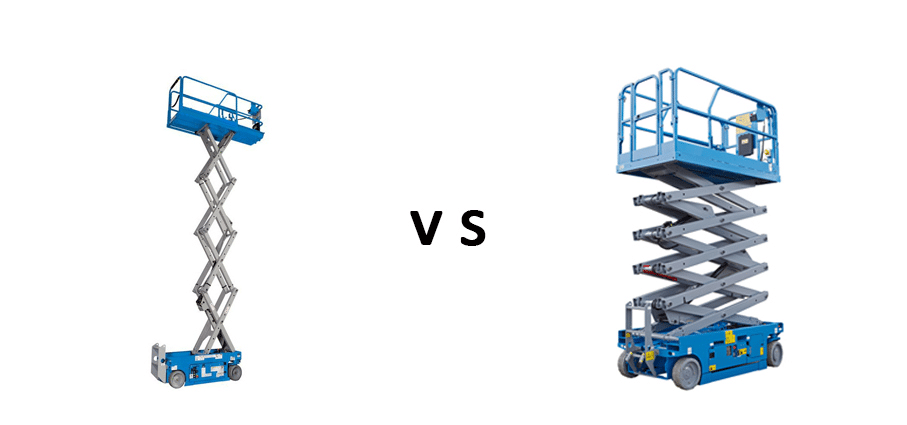

Scissor Lifts vs Boom Lifts, what is the difference?

Scissor Lifts vs Boom Lifts, what is the difference? Concept of the Scissor Lifts & Boom Lifts Aerial Working Platform that serves various industries in high-altitude operations, equipment installation, maintenance, and other mobile high-altitude operations. Aerial work platform is a…

Scissor Lift Size: How To Select The Right Height For Your Scissor Lift?

Scissor Lift Size: how do select the right height for your scissor lift? When you are considering selecting a scissor lift for your business, you must consider what is the most suitable size or height for your usage. An appropriate height…

10 Basic Boom Lift Safety Tips for the Operators

10 Basic Boom Lift Safety Tips for the Operators The boom lifts are widely used by construction companies for high-area jobs. Safety has always been a hot topic that has been discussed since ancient times. However, since entering the new generation, boom lift technology…

OSHA Standards For Scissor Lift Safety Complete Guide

OSHA Standards For Scissor Lift Safety Complete Guide OSHA standards define a scissor lift as a Scaffold but not an aerial lift because the scissor lift is typically fixed, not vehicle-mounted. According to OSHA stands, an aerial lift is something that…

How To Operate A Boom Lift?

The boom lift aerial work platform, as a classic aerial work equipment suitable for indoor and outdoor multi-point operations, is renowned for its excellent ductility, heavy load capacity, strong power, easy maintenance, and high energy efficiency. It has a wide…

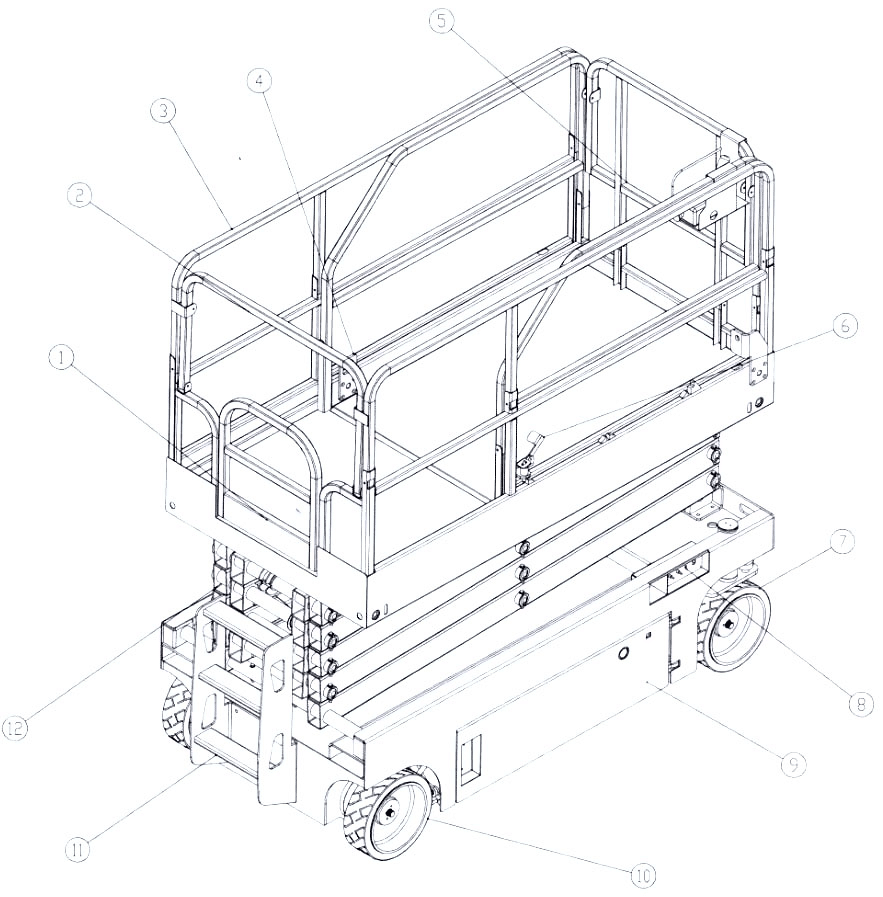

The Scissor Lift Guide | Definition, Classification Types and Application

What is the scissor lift? The scissor lift is one type of high aerial work platform man lift and widely used on commonly interior work jobs like ceiling construction, sign hanging, lifting people, materials, and other maintenance projects. Compare to…

What Is The Jib On Boom Lift?

What is the Jib on Boom lift? Conception & Application The Jib on the boom lift is the final transmission and load-bearing part of the force. The absolute force of the jib must be strong enough to maintain the stability of the high-altitude…

What is a Boom Lift: Definition, Types and working principle

Boom Lift: Definition, Types and working principle Concept of Boom Lift Boom Lift is a common lifting equipment in higher height aerial working platform solutions between telescopic boom lift & articulated boom lift, mainly composed of the following parts: The above are the…

How To Operate The Scissor Lift?

How To Operate The Scissor Lift? The Scissor Lifts The self-propelled scissor lift is a mechanical equipment used for high-altitude operations, which can perform safe and efficient operations indoors and outdoors. To ensure the safety of operators and the smooth…

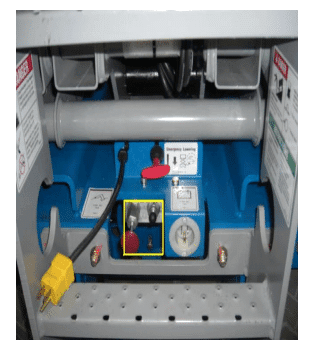

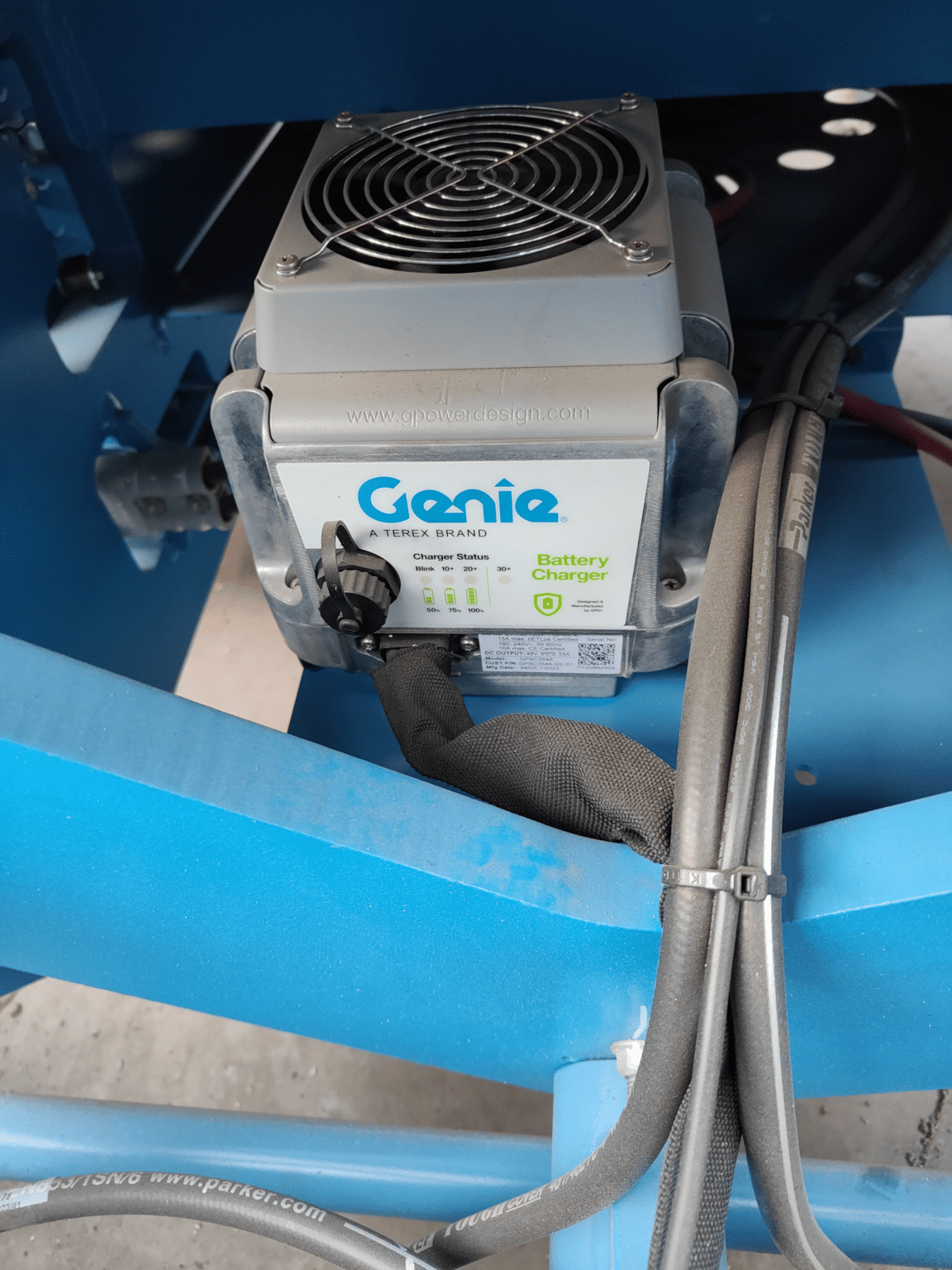

How To Charge The Scissor Lift?

How To Charge The Scissor Lift? When we buy or rent a scissor lift, we may confused about how to charge a scissor lift properly. Due to these types of electric scissor lifts are battery-powered, they require to be charged…

Narrow Scissor Lift vs Wide Scissor Lift, What Is The Difference?

Narrow Scissor Lift vs Wide Scissor Lift, What Is The Difference? When we classify a scissor lift, there are 2 main types popular on the market, narrow scissor lift and wide scissor lift. They are both efficient for high areas works which…