Is Fall Protection Required On Scissor Lift?

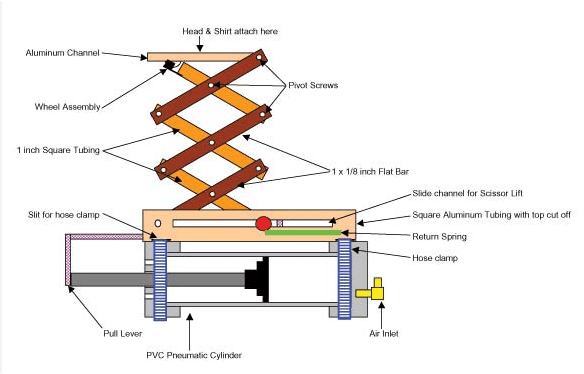

Scissor lifts have a wide range of applications in fields such as construction, logistics, and warehousing. It provides a convenient and efficient solution for workers to transport and lift heavy objects, saving time and costs, and improving work efficiency and safety.

The traditional manual handling method not only consumes a lot of manpower and time, but also poses safety risks. The scissor lift is equipped with a powerful mechanical lifting system and a stable working platform, which can easily carry a large amount of heavy objects and move quickly. In addition, scissor lifts are indispensable in high-rise building construction. It can quickly transport materials and personnel vertically from low floors to high floors in a short period of time, greatly improving construction efficiency.

At the same time, scissor lifts can also provide safety protection for construction workers, placing them on stable and safe work platforms, reducing the danger of working at heights. It can also be adjusted and modified according to different construction needs, such as being used as a temporary work platform in exterior wall decoration projects and as a freight scissor lift in interior decoration projects.

In the logistics and warehousing industry, scissor lifts are commonly used for loading, unloading, and handling goods. It can lift goods from the ground to the shelves or unload them from the shelves, improving the efficiency of logistics warehousing. Its simple structure, flexible operation, and safe and reliable characteristics enable it to achieve height adjustment and handling of goods in small spaces.

For example, in the process of storing new energy raw materials in the warehouse, after unloading from the vehicle and entering the storage line, the lifting and transfer action can be completed by a scissor lift; The process of transferring goods from the conveyor line to the ground vehicles in the finished product warehouse of large metal processing enterprises also relies on scissor lifts.

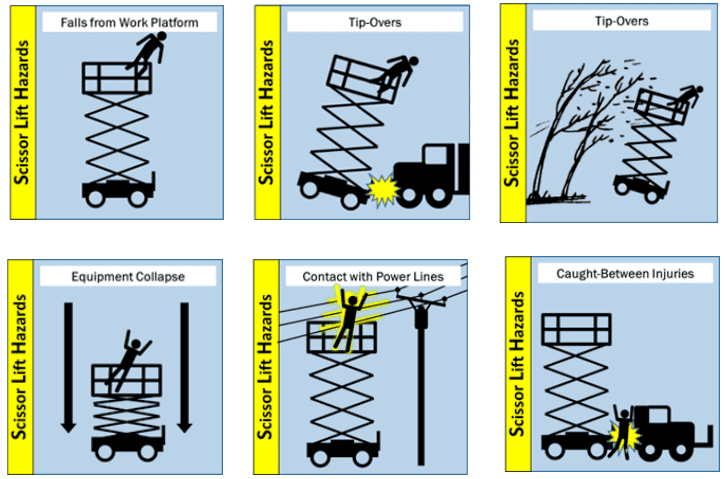

Potential safety hazards of scissor lifts

1. Falling down risk

Scissor lifts may face the risk of overturning at construction sites. For example, if operating on uneven ground, the stability of the scissor lift will be greatly affected. When the scissor lift is on uneven ground, the uneven force on each leg may cause some legs to deform or sink due to excessive pressure.

In this case, the scissor lift is prone to losing balance and overturning. Once overturning occurs, it will not only cause serious damage to the scissor lift itself, but also endanger the safety of personnel working on the scissor lift, which may result in injury or even life-threatening situations.

2. Scratch risk

During use, the scissor lift may rub against surrounding objects. Construction sites are usually complex and may be surrounded by buildings, equipment, materials, etc. If the operator is not careful enough when operating the scissor lift or makes inaccurate judgments about the surrounding environment, it is easy for the scissor lift to rub against surrounding objects. Scratching may damage the shell and structure of the scissor lift, affecting its normal use. Severe scratching may also cause damage to the control system of the scissor lift, causing the scissor lift to lose control and leading to more serious safety accidents.

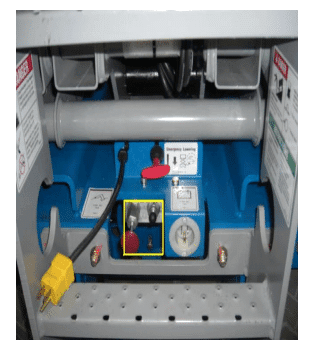

3. Electric shock risk

There may be a risk of electric shock in the construction electricity supply. If wires are randomly connected, it is easy to cause wire damage and leakage. During the operation of a scissor lift, if it comes into contact with a leaking electrical wire, it can cause the lift to become electrified, endangering the safety of the operator and surrounding personnel.

In addition, if the electrical system of the scissor lift does not have good grounding protection, it will also increase the risk of electric shock. Once an electric shock accident occurs, the consequences are unimaginable and may cause casualties.

Why do scissor lifts need fall protection?

1. The danger of working at heights

Scissor lifts are mainly used for high-altitude operations, and workers face a great risk of falling from heights during high-altitude operations. Once an accident occurs at high altitude, the consequences can be unimaginable. For example, when a scissor lift malfunctions or is operated improperly, workers are likely to lose their balance and fall from a height, which not only poses a serious threat to their safety but also causes huge losses to their families and society. Therefore, fall protection is particularly necessary in the use of scissor lifts.

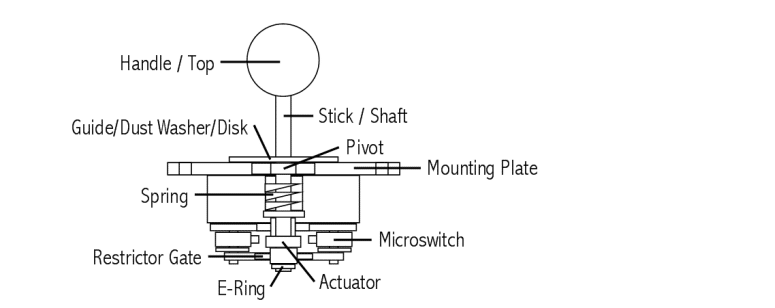

2. Improve security

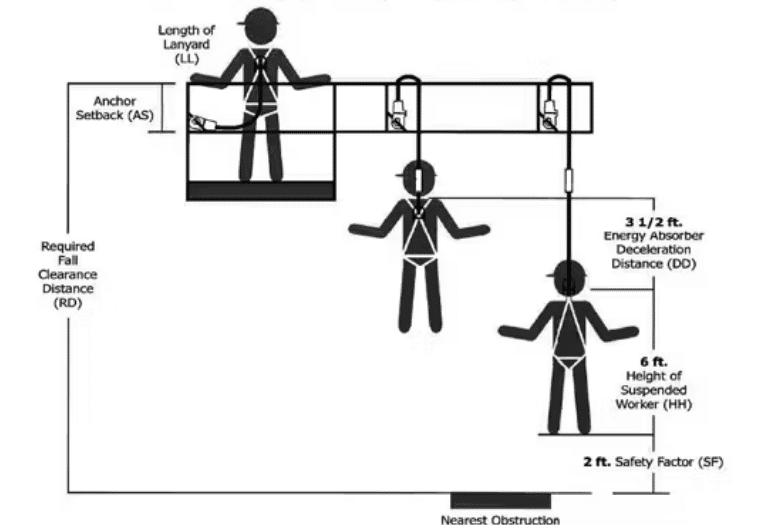

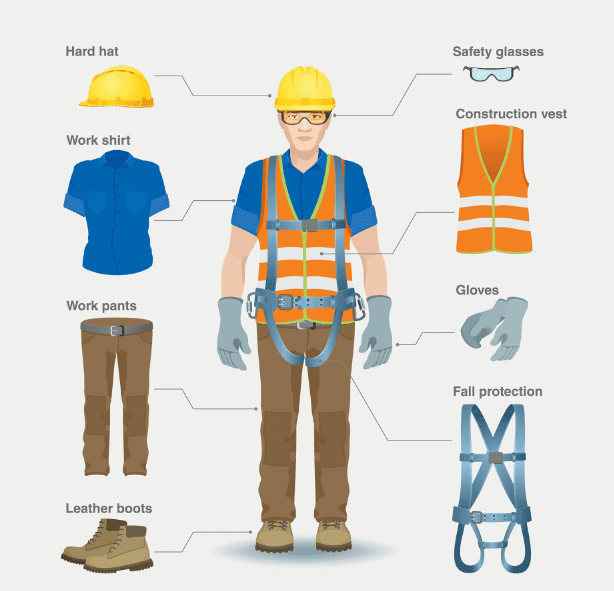

Fall protection devices such as safety belts, ropes, etc. can greatly improve the safety performance of scissor lifts and protect the lives of workers. Like some anti fall scissor lifts, there are fixed poles in the middle of the work platform with ropes attached. Workers can tie the ropes tightly around their waist when working at heights to prevent falls. At the same time, many scissor lifting platforms require users to wear full body safety belts.

During the lifting process, the safety belt should be fastened to the platform, basket, or manufacturer’s fastening point. When lifting to the working height, the safety belt should be fastened to other structurally reliable fastening points.

If there is no reliable fastening point, a steel wire rope should be used to tie it to the steel beam or concrete beam, and the safety belt should be fastened to the steel wire rope loop. These fall protection devices provide a solid safety line for workers working at heights, effectively reducing the risk of falling from heights.

Anti fall protection measures for scissor lifts

Safety identification of equipment body

The label on the scissor lift body usually contains important information such as the lifting speed limit and rated load capacity. These tag contents are crucial for safe operation. The sign indicating the limit of the rising speed reminds operators not to exceed the specified speed during use to ensure the stability and safety of the equipment. The identification of rated load capacity specifies the maximum weight that the scissor lift can withstand, and operators must strictly follow it to avoid equipment damage or safety accidents caused by overloading.

Operator training and certification

It is crucial for operators to participate in training on fall protection and the use of lifting vehicles. Through professional training, operators can fully understand the working principle, safety operating procedures, and emergency response measures of scissor lifts. Meanwhile, holding the corresponding certificate is a necessary condition for operating a scissor lift. The acquisition of the certificate means that the operator has undergone strict assessment and possesses the ability and knowledge to operate scissor lifts, which can effectively reduce operational risks.

Safety warning signs

Setting up safety warning signs around scissor lifts plays an important role. For example, height restriction signs can remind operators not to exceed the specified height during use, avoiding equipment instability or collision accidents caused by excessive height. The load limit sign specifies the maximum weight that the scissor lift can withstand, preventing safety issues caused by overloading. These signs can effectively enhance the safety awareness of operators and surrounding personnel, and reduce the occurrence of safety accidents.

Prevent overloading and excessive height

Clear load and height restrictions are crucial for the safe operation of scissor lifts. Operators should closely monitor the load and height situation through the equipment display device to ensure that they do not overload or exceed the height limit. Before use, the lifted items should be accurately weighed and measured to ensure that they are within the specified load and height range. At the same time, operators should strictly follow the operating procedures and not increase the load or height without authorization.

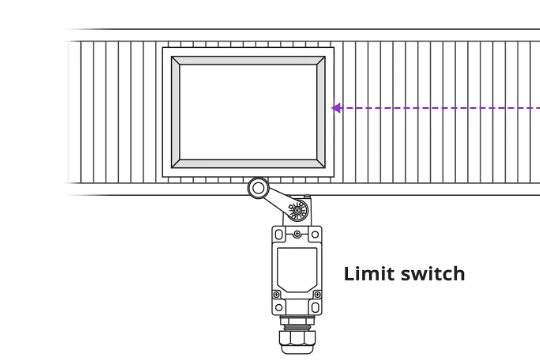

Safety guardrails and safety devices

The safety guardrail of the lifting platform is an important facility to prevent personnel from falling. Safety guardrails should have sufficient height and durability to effectively prevent accidental falls of personnel. In addition, safety devices such as limit switches and emergency stop switches also play a critical role. The limit switch can automatically stop running when the scissor lift reaches its limit position, preventing accidents caused by excessive lifting. The emergency stop switch can quickly stop the operation of the scissor lift in case of emergency, ensuring the safety of personnel.

Monitoring and Security Alarm Devices

Installing monitoring devices and safety alarm devices can promptly detect abnormal situations and take measures. The monitoring device can monitor the operation status and surrounding environment of the scissor lift in real time. Once abnormal situations are detected, such as overload, over height, equipment failure, etc., it can issue an alarm in a timely manner. The safety alarm device can remind operators and surrounding personnel to pay attention to danger through sound or light signals, so as to take timely response measures.

Risk assessment and emergency plan

Conducting risk assessment and developing emergency plans are crucial for the safe use of scissor lifts. Risk assessment can comprehensively analyze potential hazardous situations and develop corresponding response strategies. The emergency plan should include emergency shutdown procedures and personnel evacuation routes. In the event of an accident, operators can quickly follow the emergency plan to minimize losses and ensure personnel safety.