How to release brakes on scissor lift?

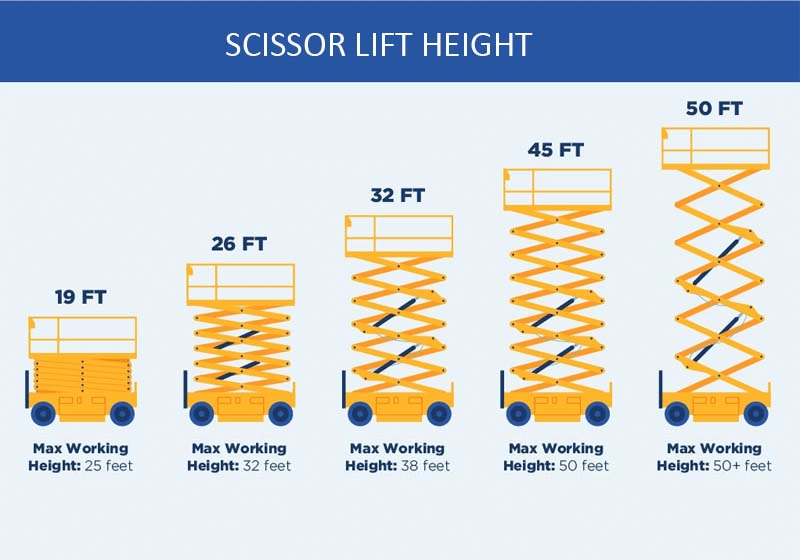

Scissor lift is a high safety equipment during using. The way the scissor lift releases the brake may vary depending on the model and manufacturer. Here are some common steps:

Check the equipment conditions

Before releasing the brake, first ensure that the scissor lift is in a safe operating environment. Check if the support feet of the elevator are firmly placed on a solid ground and if there is no load exceeding the rated load on the lifting platform. At the same time, confirm that the power connection is normal or that the hydraulic system is in normal working condition (depending on whether the elevator is electrically or hydraulically driven).

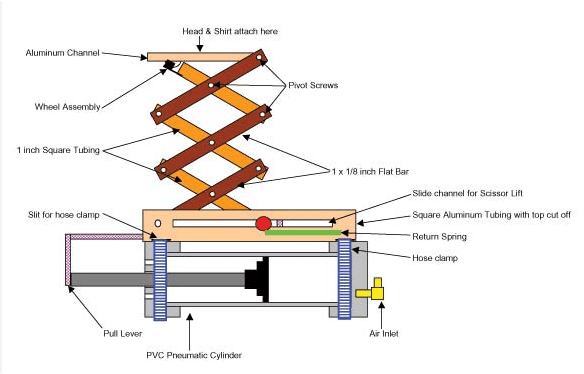

How Does Scissor Lift Work?

Steps for releasing the brake of an electric scissor lift

1. Key start

Most electric scissor lifts control the start and partial functions of the equipment through a key switch. Insert the key into the keyhole of the control box, and then turn the key to the “open” position. This step usually activates the electrical system of the device, providing power support for subsequent operations such as releasing the brake.

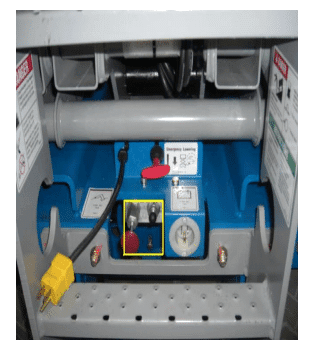

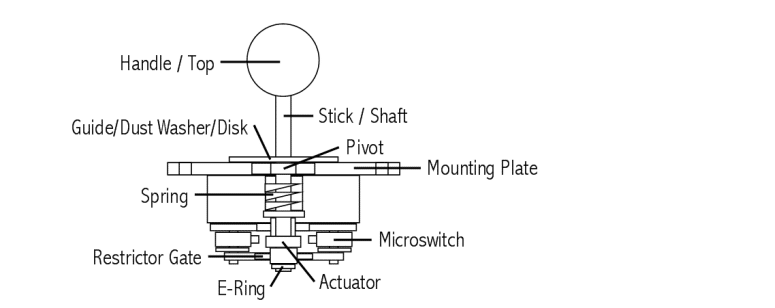

2. Find the brake control button or switch

Search for buttons or switches specifically designed to control the brakes on the control box or operation panel. This button may be labeled with words such as’ Brake Release ‘or’ Brake Release ‘. Some elevators may also have a brake release button with an indicator light. When the button is pressed, the indicator light will light up, indicating that the brake is being released.

3. Press the brake release button

Press and hold the brake release button found. During the process of releasing the brake, a slight mechanical sound may be heard, which is the normal sound of the brake device releasing the brake. At the same time, pay attention to observing whether there is any abnormal movement or vibration of the elevator. If any abnormal situation occurs, immediately release the button and check the equipment.

Steps for releasing the brake of hydraulic scissor lift

1. Check the hydraulic system

For hydraulic scissor lifts, it is necessary to ensure that the oil in the hydraulic oil tank is at a normal level and that there are no obvious signs of leakage or damage to key components such as the hydraulic pump. If the hydraulic oil is insufficient, it may affect the normal lifting operation after the brake is released.

2. Operate hydraulic control rods or valves

-The brakes of hydraulic scissor lifts are usually interrelated with the hydraulic system. Find the control rod or valve that controls the hydraulic system in the operating area of the equipment. Some devices may have a small valve specifically designed to release the brake, which can be rotated to release the hydraulic pressure of the brake. Some devices also move the main hydraulic control lever to a specific “release brake” position. This position may be at the initial start position of the control lever or have clear markings indicating it.

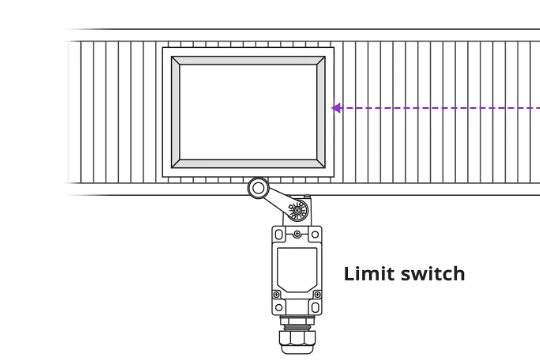

3. Confirm that the brake is released

After operating the hydraulic control device to release the brake, also pay attention to whether there are any abnormal conditions in the equipment. You can gently push the lifting platform to check if the brake has indeed been released and the platform can move freely.

Steps of release the Genie scissor lift brakes

Step 1: Make sure wheels are chocked. Locate brake release manifold at rear of machine.

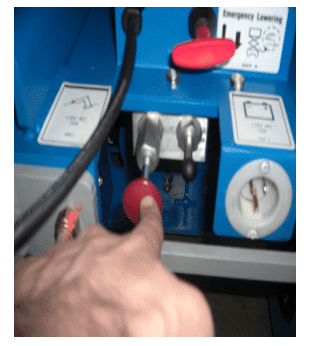

Step 2: Units with round or dome shaped knob: press knob in Units with round coin shaped knob: turn knob CCW.

Step 3: Pump red knob to release brakes.

Step 4: To reactivate brakes on units with round or dome shaped knob drive unit with wheels chocked and the black knob will pop back out. To reactivate brakes on units with round coin shaped knob rotate knob CW then drive the unit with wheels chocked. The brake should now be back in the normal operating position.

Regardless of the type of scissor lift, when performing lifting operations after releasing the brake, the operator must strictly follow the instructions in the operation manual and always maintain caution and pay attention to safety. If you still have doubts about the operation of releasing the brake, it is best to consult the manufacturer or professional maintenance personnel.