Understanding the Role of Joysticks in Scissor Lifts and Boom Lifts

What Is A Joystick?

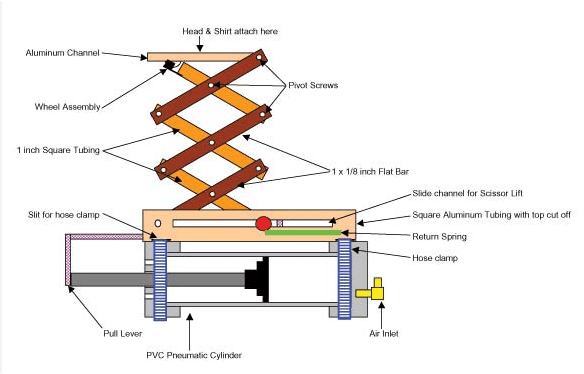

A joystick on a scissor lift/boom lift is a physical input device which can convert the movement of a plastic rod into electronic information that can be processed by a computer. Scissor lifts and boom lifts are highly favored for their stable performance and flexible operation ability.

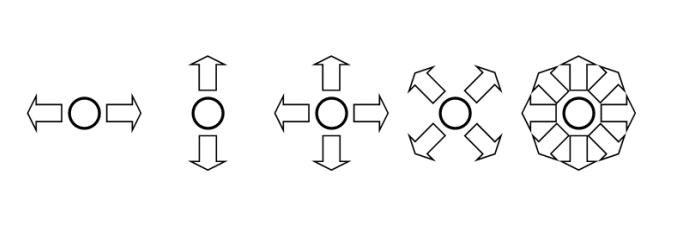

In the operating system of the scissor lift and boom lifts, the joystick is an important part of controlling them. These joysticks are built with continuous states, returning an angle measure of the movement in any direction of the given plane usually using potentiometers. The use of joysticks took the place of digital joysticks, which were limited to only four directions (left-right and up-down).

How does the joystick work on the scissor lift/boom lift?

The basic principle of a joystick is to convert the movement of a plastic rod into electronic information that can be processed by a computer. When in use, replace according to the required speed. The function of the sense of operation is to shift gears according to the driving situation.

At the other end of the motor, its shaft is connected to the position sensor of the joystick (such as a voltage divider or optical sensor). As long as the joystick moves, the sensor can detect the position of the joystick, whether it is caused by the motor or the player.

The scissor lift joystick is usually the main control device for interaction between the operator and the equipment. Its design aims to provide operators with convenient, precise, and intuitive control methods to command various actions and functions of the scissor lifts.

How To Replace A Joystick For Scissor Lifts and Boom Lifts?

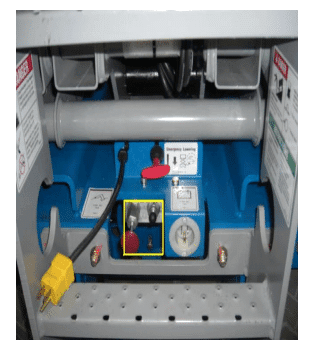

- Ensure the equipment is power off before replacing the joystick.

- Ensure the red emergency button is pulled out.

- Remove the control box from the bracket.

- Open the control box and then disconnect the wires.

- Remove screws from the joystick mounting.

- Remove the old joystick, and install the new joystick into the control box.

- Apply dielectric grease on wire terminals and re-connect the wires.

- Re-assemble the control box.

- Turn on the equipment to test the function for the new joystick.

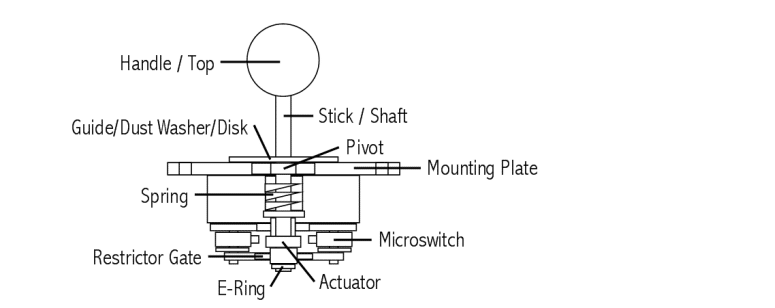

The design of a joystick

Typically, the shape and size of the joystick may vary depending on the model number and manufacturer of the scissors, but their basic functions and operating principles are generally the same.

Generally speaking, joysticks are designed ergonomically to ensure comfort and reduce fatigue for operators during prolonged use.

A joystick is typically made of the following parts:

- Handle/Top

- Stick/Shaft

- Guide/Dust washer/Disk

- Pivot

- Spring

- Mounting plate

- Restrictor Gate

- Micro-switch

- E-ring

- Actuator

What is the function of a joystick?

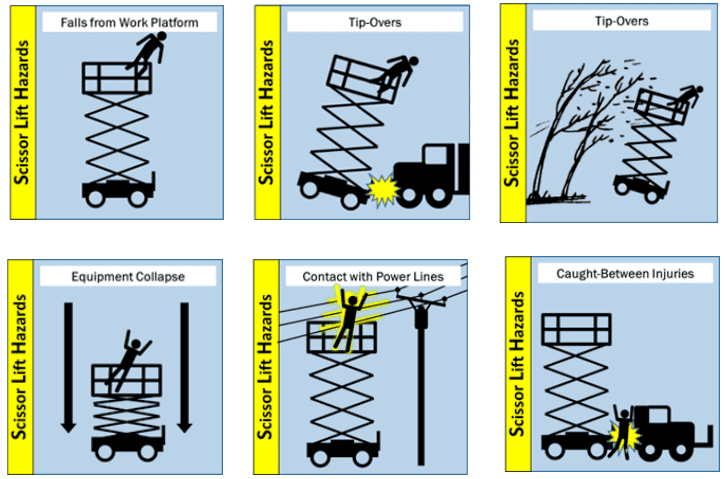

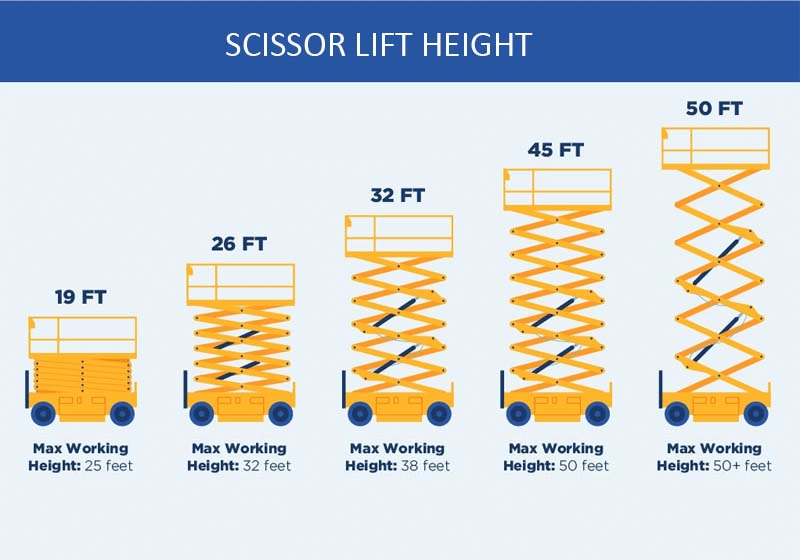

When we talk about the function, the joystick is mainly used to control the basic movements of the scissor lifts and boom lifts, such as up, down, forward, backward, and steering. By manipulating the joystick in different directions and with varying degrees of force, operators can accurately adjust the position and posture of the scissor lifts, enabling it to safely and efficiently reach the high work area.

For example, pushing the joystick forward may cause the scissor lifts to move forward, while pulling it backward may cause it to move backwards. Turning the joystick to the left or right can achieve steering operation of the vehicle. The joysticks for ascending and descending can adjust the height of the work platform to meet the operational requirements of different heights.

In addition, some advanced scissor lifts joysticks may be equipped with additional function buttons or switches, such as emergency stop buttons, speed adjustment buttons, etc., to further improve the safety and flexibility of operation.

To ensure that operators can proficiently and accurately use the joystick, specialized training and guidance are usually required before using the scissor lifts. Operators need to understand the functions of each functional component of the joystick, master the correct operating techniques and force, and be familiar with operating skills under different working conditions.

What is the type of scissor lift joysticks?

For scissor lifts and boom lifts, joystick is a part for controlling the operation. The difference in the type of joystick directly affects the convenience and safety of operation.

The common types of scissor lift joystick are as follows:

Mechanical joystick

Mechanical joystick is the traditional type. It is connected to the lifts’ control system through a mechanical linkage, and the operator directly pushes or pulls the joystick to convey instructions. This type of joystick has a relatively simple structure and high reliability, but the operating feel may be stiff and require a greater amount of force from the operator.

Advantages

- Directly mechanical transmission.

- Rapid response.

- Ability to provide accurate control for some operations that require precise control, such as fine-tuning in small spaces.

Disadvantages

- Mechanical components are prone to wear and require regular maintenance and upkeep.

- Due to the limitations of the mechanical structure, the flexibility and comfort of operation not as good as other types.

Electronic joystick

Electronic joysticks have gradually become more popular. It converts the operator’s actions into electrical signals through sensors and transmits them to the vehicle’s electronic control system, thereby achieving control of the scissor lifts.

Advantages

- Light , Comfortable and easy to control.

- Provide more delicate and precise control, making the movements of the scissor lift smoother and more fluid.

- Electronic joystick can also be integrated with the vehicle’s intelligent system to achieve functions such as fault diagnosis and operation recording.

Disadvantages

- Maintenance costs are higher.

- In some extreme environments such as high temperature, high humidity, etc., the stability of electronic components may be affected.

Wireless joystick

Wireless joystick is developed based on electronic joystick, which communicates with scissor car through wireless signals. This type of joystick breaks free from the constraints of cables, allowing operators to move freely within a larger range, improving work flexibility and efficiency.

Advantages

- Provide operators with larger space for movement

- More flexible

Disadvantages

- Interference or signal interruption may affect the safety of operations.

- the wireless joystick requires regular charging or battery replacement to ensure its proper functioning.

Different types of scissor-lift joysticks have their advantages and disadvantages. In practical applications, users should choose the appropriate joystick type based on specific job requirements, working environment, and budget factors. Regardless of the type of joystick, operators need to undergo professional training and familiarity to ensure safe and efficient operation of the scissor lift to complete high-altitude work tasks.

common joystick brand

In summary, the joystick of the scissor lifts is a key control component for achieving efficient and safe operation of the scissor lifts. Its accuracy and reliability directly affect the work efficiency and safety of operators, and it is an indispensable and important component of scissor lifts.