Factory Solutions

The Procter & Gamble factory located in the Taicang Port Development Zone is the 10th factory of this global consumer goods giant in China, and it is also one of Procter & Gamble’s largest production bases in Asia. After completion, it will become a distribution center that integrates production and logistics bases.

A high-quality work environment starts from the moment of breaking ground. Procter & Gamble’s “Garden Factory” has almost strict standards in construction, starting with safety and ensuring zero accidents and injuries during construction.

Therefore, Procter & Gamble has invited two internationally renowned project management companies, Wally Parson and Meswell, to be responsible for construction management, both of which have strict requirements for construction safety. In the selection of construction equipment, the project management requires that all construction involving high-altitude operations be carried out using high-altitude operation platforms. And this is not the only mandatory requirement, as products from different brands also need to undergo further screening by management.

Application of the MEWP in the Factory

Super Stability Helps to Complete the Rigid Structure On Time

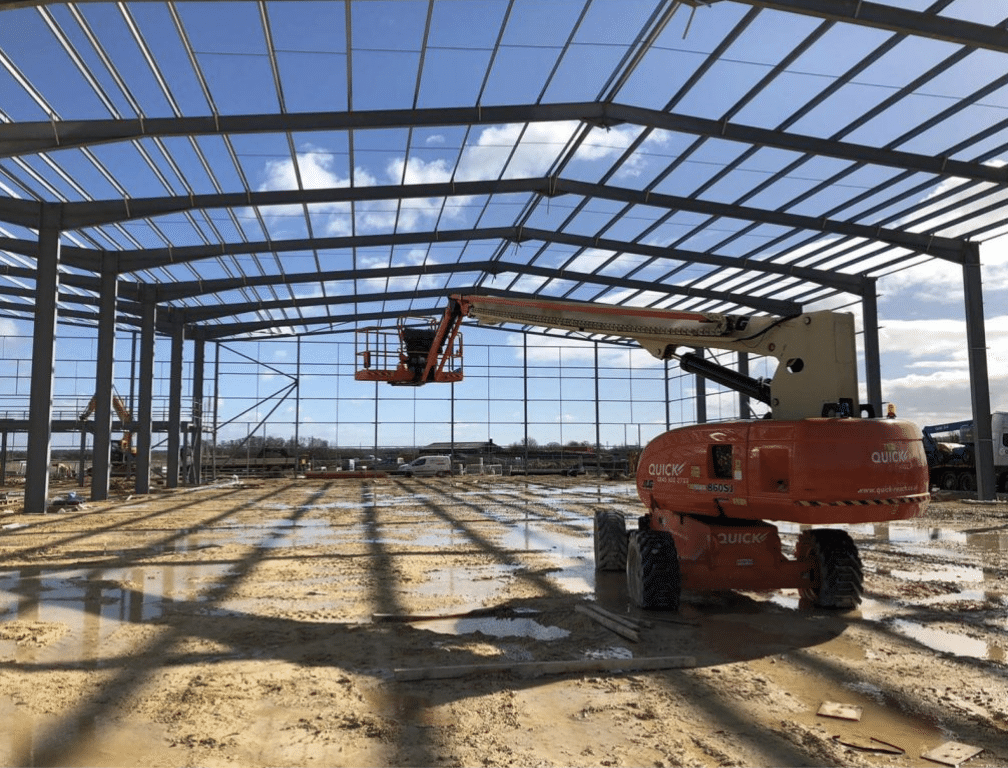

Steel structure construction is the first step of the entire factory construction and the cornerstone of the orderly progress of subsequent construction. The length of its construction period will directly affect the progress of the entire project, so the management requires that steel structure construction must be completed within 3 months.

Faced with such a large-scale construction, a 3-month construction period is full of challenges, which puts higher demands on the stability of construction equipment. Equipment should not delay the construction period due to malfunctions.

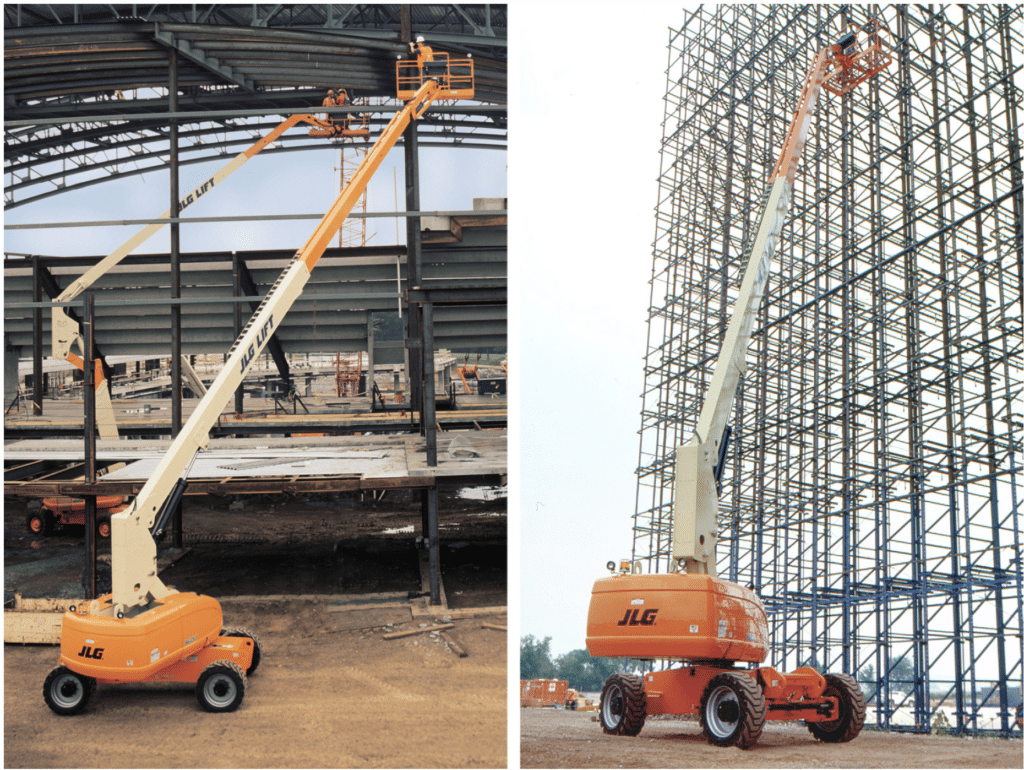

JLG’s 860SJ and 660SJ straight-arm high-altitude work platforms are the main models for steel structure construction. More than 10 orange high-altitude work platforms are active at the construction site, day and night, becoming beautiful scenery on the construction site. During the entire three-month construction process, JLG’s high-altitude work platform has demonstrated exceptional stability.

More than ten units took more than 90 days, but only three repairs were reported. Moreover, due to JLG’s excellent service system, they were quickly resolved without affecting the construction progress, laying a good foundation for subsequent construction projects.

72 ft Used Boom Lift, JLG 660SJ (2011)

Efficient Performance Subverts Traditional Construction Methods

In the interior decoration stage of Procter&Gamble’s Taicang factory, The JLG 3246ES scissor-type high-altitude work platform has almost contracted for the high-altitude work part of all interior decoration projects.

Sometimes, there will be 20 JLG equipment working simultaneously, responsible for the installation of indoor fire protection, mechanical and electrical, and water supply and drainage. Compared to traditional scaffolding construction, JLG 3246ES not only provides better security but also greatly improves work efficiency.

Regarding the convenience brought by advanced equipment, like the charger sighed, “In the past, construction workers needed to frequently climb scaffolding and rely on manual labor to move equipment, which not only lacked safety guarantees but also was time-consuming and laborious. Now, they can quickly move with simple operations on the platform. These are all disruptive changes.”

32 Ft Used Scissor Lift, JLG ES3246 (2023)

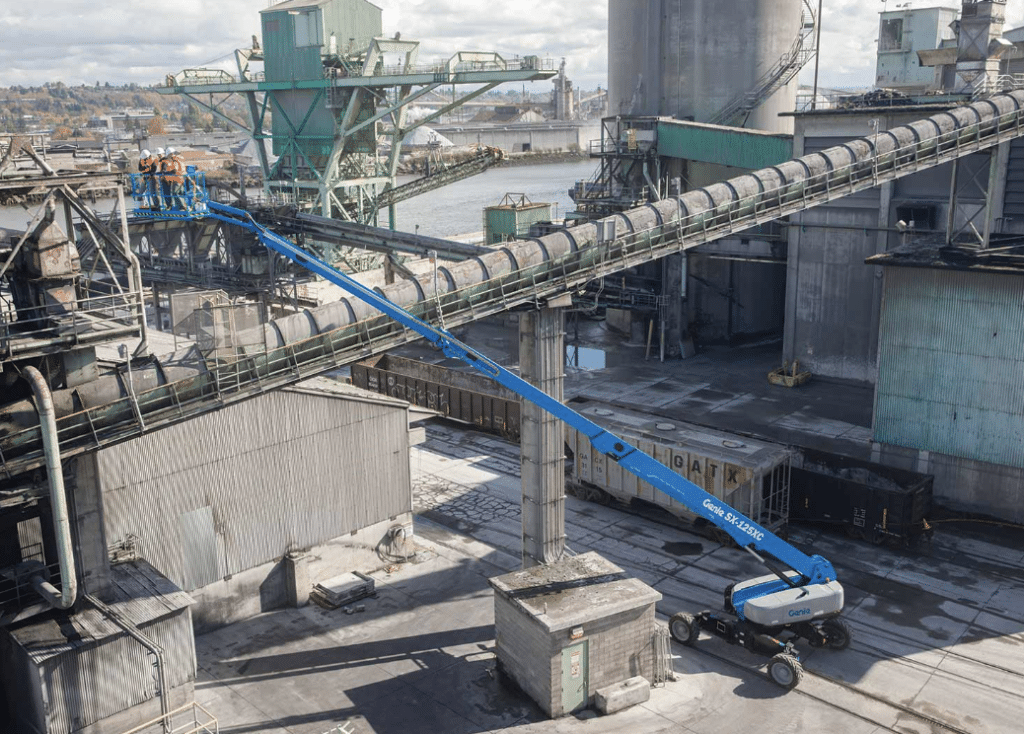

Flexible Posture to Easily Cope with Complex Working Conditions

Unlike ordinary steel structure factories, Procter&Gamble Taicang Factory also requires the installation of external chemical pipeline devices. Chemical storage tanks and pipelines involve valves and fittings with a wide range of specifications and quantities, all of which have the characteristics of high temperature, high pressure, flammability, and explosiveness.

The construction requirements are particularly high, and operators need to be accurately positioned at the construction site. Ordinary high-altitude equipment cannot complete such complex and precise tasks. The emergence of the JLG E450 series curved arm high-altitude operation platform provides a perfect solution for this special working condition.

With flexible arm bending ability, The E450 can span and extend to any corner of pipeline installation, performing exceptionally well in moving forward and backward, completing tasks that were originally impossible.