Airport Solutions

From hangar maintenance and material loading to pre-delivery and flight route inspections, a high-altitude work platform always suits your needs.

With the TacMan high-altitude operation platform, once difficult-to-reach areas on the aircraft (under the wings, around the fairing, above the fuselage, and tail) are now within reach.

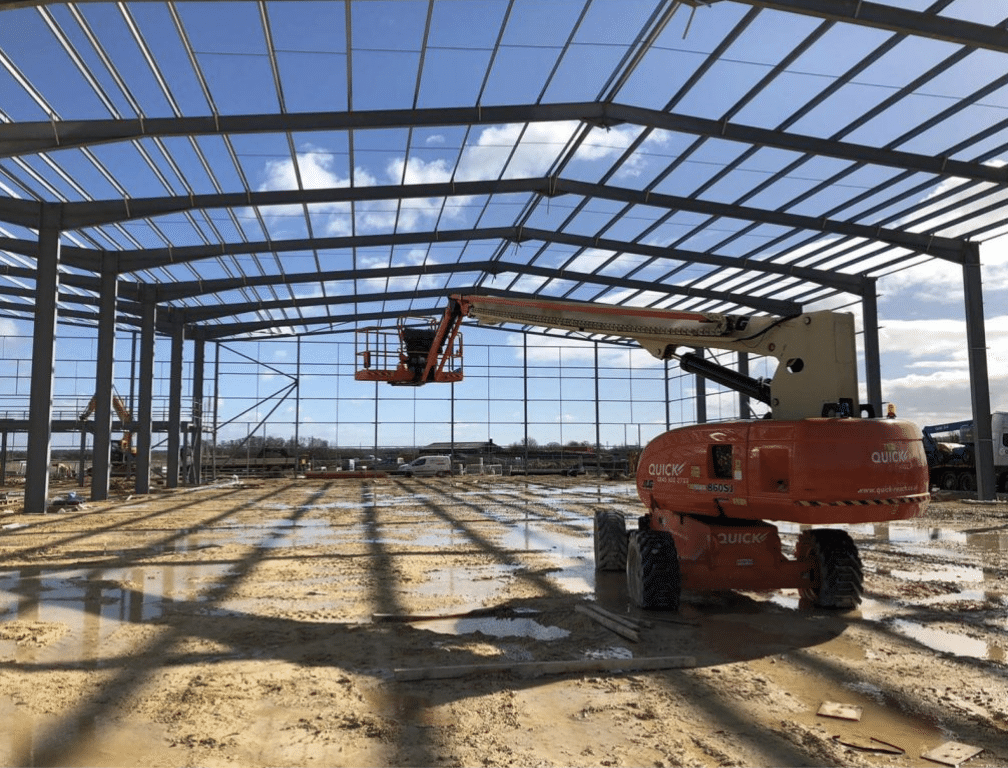

The scissor lifts is specialized equipment for high-altitude work, suitable for various indoor and outdoor high-altitude work maintenance.

why not use a crane or ladder for high-altitude operation maintenance?

In some workplaces, such as indoor airport terminals and train station waiting halls, cranes cannot enter and ladders cannot reach the working height. In addition, the cost of hiring cranes for outdoor shed roof maintenance and wall painting is too high, and ladders are not convenient to move. Therefore, scissor-type high-altitude work lifting platforms have become the best choice.

The scissor lift has replaced traditional ladders and can move vertically, making it more widely used. When working on high-altitude lifting platforms, workers need to wear protective equipment such as fall arresters, safety belts, and safety ropes. The fall arresters should be hooked onto the fence of the high-altitude lifting platform to prevent high-altitude falling accidents.

Before starting work, carefully check the lifting speed limit and rated load capacity of the high-altitude operation platform, and operate according to the requirements of use. Move on the open ground of the platform, do not operate on uneven ground, as it is prone to danger.

The platform operation area must be maintained with warning tapes and warning signs set up. When moving the high-altitude operation lifting platform, the speed should not be too fast, it should be kept stable, and obstacles should be avoided.

If used frequently, the maintenance and repair of The scissor lift is particularly important, which can effectively reduce component damage, extend the service life of the equipment, improve work efficiency, and enhance the safety of the operation.

Recommendation of the MEWP in Airport

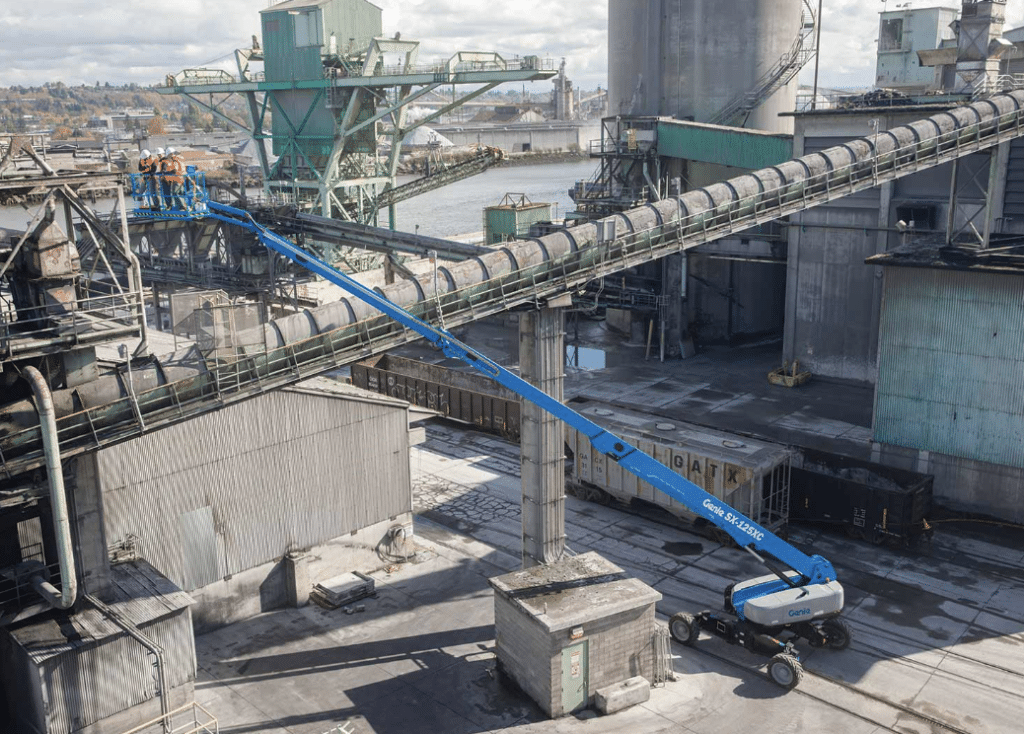

High altitude work platforms are now a new auxiliary tool for aircraft maintenance, and JLG has launched a specialized high-altitude vehicle for this purpose. It not only improves the overall efficiency of aircraft maintenance but also shortens the nonservice time of the aircraft, assisting in maximizing the utilization of the hangar and surrounding airspace.

Compared to the particularity of the overall structure of the aircraft, the JLG high-altitude operation platform can provide the most effective solution according to the different situations of each part.

Compared to the maintenance and upkeep of aircraft fuselage and large wings. The JLG 800AJ articulated booms can easily reach any position, including the Boeing 747 model, with its ultra-long crossing ability.

86 ft Used Boom Lift, JLG 800AJ (2011)

Compared to aircraft tail wing maintenance. According to different heights, JLG scissor lift can be selected to reach the working position, both of which are very convenient.

Compared to engine and landing gear maintenance. Scissor type, mast type, articulated booms, or telescopic booms can be selected. Their compact exterior dimensions and certain horizontal extension ability make it easier for aircraft maintenance personnel to reach the corresponding positions.