How does scissor lift work?

Scissor lift is a device like its name which uses a “scissor” design structure to achieve lifting and lowering functions, and is currently widely used for indoor and outdoor jobs. It is small in size and easy to move between different places; Flexible to use and able to adapt to various complex working conditions; High cost-effectiveness, compared to other high-altitude operation equipment, while meeting the operational needs, the cost is relatively low.

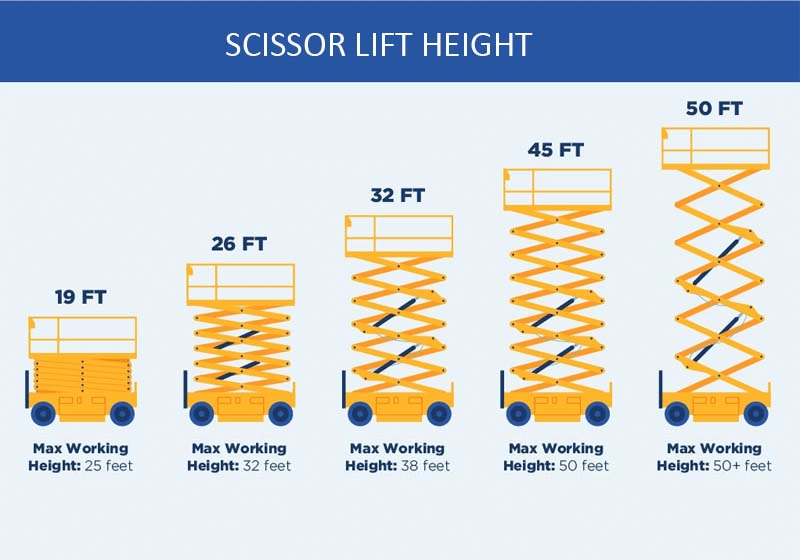

Scissor lifts are commonly used in high-altitude work environments such as construction, exterior wall maintenance, advertising installation, and signal light installation. It is stable and safe, with a large operating range and a working height generally ranging from 6 meters to 18 meters.

For example, the Genie rough terrain off-road scissor car has strong power, is driven by a 36kW engine, four-wheel drive, and has a climbing ability of up to 40%, which can adapt to various harsh working conditions. Full height driving saves time on repeated lifting and improves work efficiency.

Working Principle

Mechanical Structure and Power System

The working principle of a scissor lift mainly involves the synergistic effect of mechanical structure and power system. It drives the hydraulic pump to work through an electric motor, converting the mechanical energy converted by the electric motor into the pressure energy of the liquid. This pressure can be applied to the cylinder through liquid, and then converted into mechanical energy that acts on the scissor mechanism.

For example, the mobile scissor lift achieves this energy conversion process under the control of the control system. By using a scissor mechanism to apply mechanical energy to the lifting platform, it is ultimately converted into potential or kinetic energy of an object, achieving the function of lifting or dropping people or heavy objects.

The Genie electric scissor lift adopts a high ground clearance design and uses high-strength body protection panels, which can easily cope with harsh working conditions on construction sites. The brand new electric drive motor adopts a fully enclosed brushless AC motor, which can resist moisture and even water environments, greatly reducing maintenance time.

In addition, the Genie electric scissor lift reduces hydraulic hoses and fittings by 70%, greatly reducing the possibility of hydraulic oil leakage and further reducing downtime. The electric scissor lift runs longer after each charge.

Based on industry standard HIRD cycle testing, the range of the Genie electric scissor lift can be increased by 30% compared to liquid drive, while reducing battery costs by 20% throughout the product lifecycle.

Control system

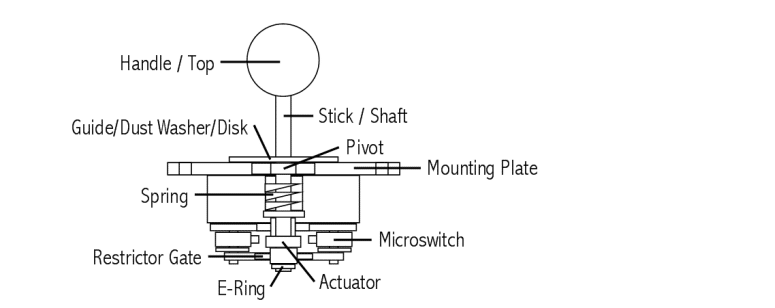

The control system of the scissor lift is easy to operate and efficient. The forward and backward operation is achieved by opening the forward, backward, and steering function buttons, pressing and holding the switch button behind the handle, and pushing the handle forward at the same time, and pulling it backward at the same time.

In the steering operation, turning left is to turn on the forward/backward and steering function buttons, press and hold the switch button behind the handle, and simultaneously press and hold the left operation button above the handle; To turn right, press and hold the right operation button above the handle. In terms of platform lifting operation, turn on the lifting function button, press and hold the switch button behind the handle, and when the handle is down, it is up, and when it is up, it is down.

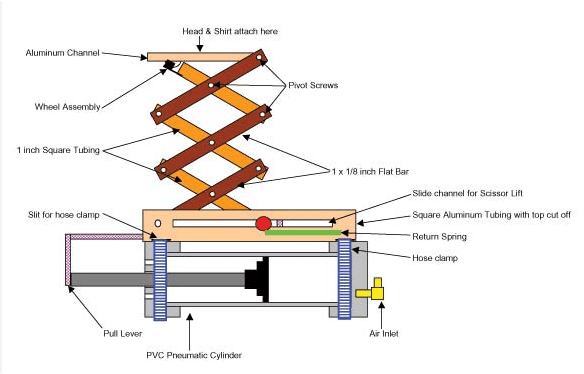

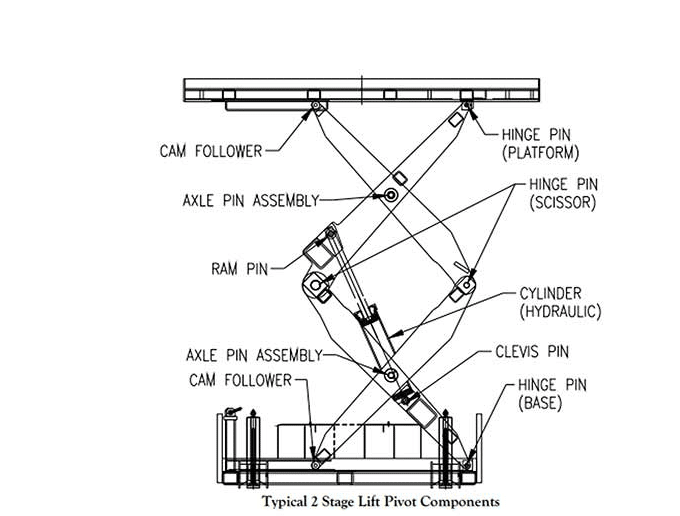

Structure of scissor lift

- The Platform: The platform support the worker and they operate on it. It locates in the top of the lift table where lifted product sits. The platform size can be different according to the models.

- Base: It is the part which support the whole equipment. This is the bottom of the structure that rests on the floor. It contains the track the scissor legs travel in.

- Scissor legs: These are the vertical members that allow the platform to change elevation.

- Hydraulic cylinder: The most common industrial scissors lifts are actuated by one, two, or three single-acting hydraulic cylinders. These allow the lift table to lift and lower.

- Motor or Power Source: Most hydraulic scissor lifts are powered by either an electric or air motor. These provide power to the hydraulic pump which actuates the lift table.

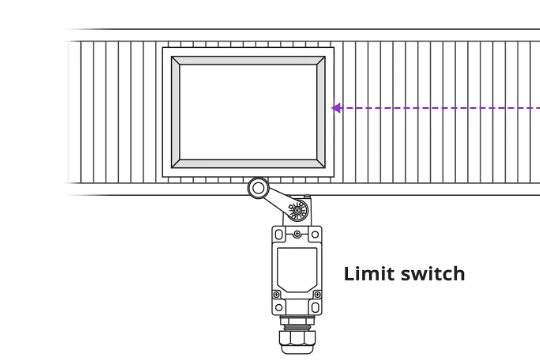

- Down valve: The down valve, which is connected to the power supply, opens when the operator uses the controls to lower the platform. The opening of the valve allows the hydraulic fluid or compressed air to leave the cylinder, which lowers the platform.

- Flow control valve: The flow control valve controls how fast the hydraulic fluid or compressed air leaves the cylinder and how fast it enters. This regulates the speed of the platform’s descent and ascent.

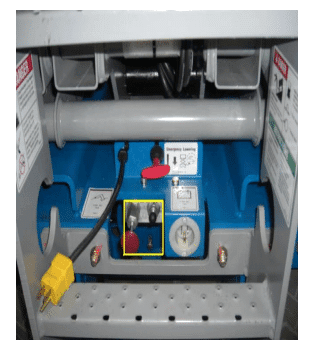

- Control panel: The control panel features an interface that allows the operator to turn on the lift, set the speed, and lift and lower the platform. These panels typically include an emergency stop button to be used in the event of a valve malfunction.

Detailed operation guide

Preparation work

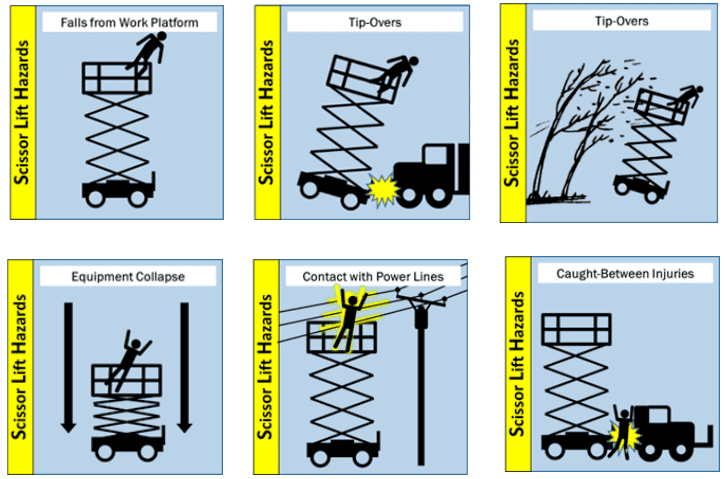

Before conducting high-altitude operations, sufficient preparation must be made to ensure the smooth progress of the operation and the safety of personnel.

Firstly, it is necessary to conduct a thorough inspection of security measures. Operators should wear personal protective equipment such as safety helmets, safety shoes, and protective goggles that comply with regulations, all of which are indispensable. Safety is of paramount importance in high-altitude operations and must not be taken lightly.

Secondly, it is necessary to conduct a safety inspection around the high-altitude crane (scissor lift). Check for loose plugs and other issues to ensure that all components of the vehicle are securely connected and there are no potential safety hazards.

After checking for accuracy, follow the correct “three-step method” to get on the equipment. Immediately fasten your seat belt after getting on the lift before performing any other operations.

Operation steps

Forward and backward operation: Turn on the forward, backward, and steering function buttons, press and hold the switch button behind the handle, and push the handle forward at the same time to move forward; Pulling backwards means retreating. During the process of moving forward and backward, it is important to maintain stability, avoid sharp turns or sudden acceleration, and slow down promptly when encountering evasive pedestrians.

Steering operation: The left turn operation is to turn on the forward, backward, and steering function buttons. Press and hold the switch button behind the handle while holding down the left operation button above the handle to turn left; The right turn operation is to turn on the forward, backward, and steering function buttons. Press and hold the switch button behind the handle while holding down the right operation button above the handle to turn right.

Platform lifting operation: When the platform is lifted, turn on the lifting function button, press and hold the switch button behind the handle while the handle is down to lift it up; When the platform descends, turn on the lifting function button, press and hold the switch button behind the handle while the handle is up to descend. During the platform lifting process, the principle of “slow lifting and smooth operation” should be followed.

Special case handling

When the scissor lift is at high altitude and the operating handle fails, emergency electronic control methods can be adopted according to different vehicle models. For example, for the 6832 scissor cart (red), turn the emergency power switch on the right side of the ladder at the rear of the work platform from the normally open position to the closed position (turn 45 ° to the right); Open the power control panel on the left side of the ladder at the rear of the work platform, press the LIFT button to the DOWN position, and the scissor cart will descend from high; Similarly, press the LIFT button to the UP position to raise the scissor cart. Attention: When the scissor cart is at high altitude, it is necessary to confirm that the telescopic platform is retracted and locked.

When the scissor lift is at high altitude, if the operating handle and ground power supply fail, mechanical emergency measures can be taken. Taking the 6832 scissor cart (red) as an example, remove the hydraulic release special tool (a 2-meter-long iron rod) from the bottom side frame of the scissor lift, wrap the head of the hydraulic release special tool around the hydraulic release valve at the bottom of the scissor cart hydraulic actuator, and rotate the hydraulic release special tool counterclockwise by about 90 degrees to loosen the hydraulic release valve.

Pull out the oil return button on the left panel of the platform ladder at the rear of the scissor cart and rotate it clockwise by 90 °. The pin on the button is inserted into the pin slot to lock the button, and the scissor cart will automatically lower. Finally, wrap the head of the hydraulic release tool around the hydraulic release valve at the bottom of the scissor cart hydraulic actuator, and rotate the hydraulic release tool approximately 90 ° clockwise to lock the hydraulic release valve. Attention: When the scissor cart is at high altitude, it is necessary to confirm that the telescopic platform is retracted and locked.

If the scissor lift fails to operate, it can be evacuated to a safe area for emergency handling. For the 6832 scissor cart (red), the brake actuator return valve on the inner side of the bottom of the platform ladder at the rear of the scissor cart is opened (turned counterclockwise), and the hydraulic oil of the brake actuator returns to the oil tank. Use a metric 19 wrench to turn the locking blocks of the hydraulic brake actuator heads on both sides of the bottom of the platform ladder at the rear of the scissor cart clockwise by 90 °, retract the hydraulic brake actuator and brake pads, and release the scissor cart brake state. Then 2 to 3 people push the scissor lift and safely evacuate it.

Conclusion

As an important Aerial equipment, scissor lift has many significant working characteristics and advantages. The scissor type structural design gives it high stability and load-bearing capacity, providing a safe and reliable working platform for operators and equipment. Whether it’s multiple people working at the same time or carrying heavy tools and materials, the scissor lift can easily handle them.

The power system is diversified, and electric, hydraulic, or internal combustion power can be selected according to different operational needs. For example, the GENIE electric scissor lift has shown excellent performance in environmental protection and energy conservation, reducing hydraulic hoses and joints, lowering the risk of leakage, while improving endurance and reducing battery costs. The control system is easy and efficient to operate, and through the combination of handles and buttons, it can achieve functions such as forward, backward, steering, and platform lifting, greatly improving work efficiency. Even in complex work environments, operators can quickly and accurately control the scissor lift.

In addition, the scissor lift is compact in size, making it easy to move between different sites and adapt to various complex construction environments. Whether in narrow indoor spaces or rugged outdoor construction sites, scissor lifts can flexibly shuttle and provide convenient solutions for high-altitude operations.