Does OSHA require a harness in a scissor lift?

OSHA, also known as the Occupational Safety and Health Administration in the United States, plays a crucial role in ensuring workplace safety. As a commonly used high-altitude operation equipment, scissor lifts have a wide range of applications in multiple fields.

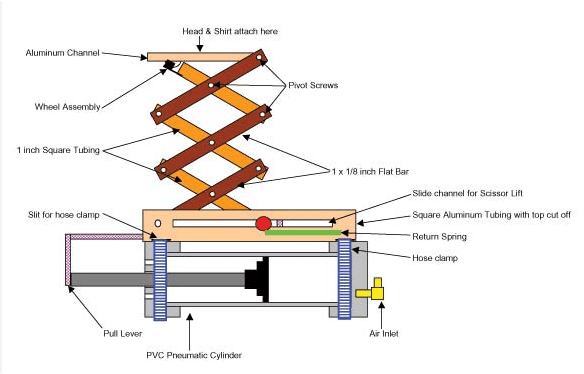

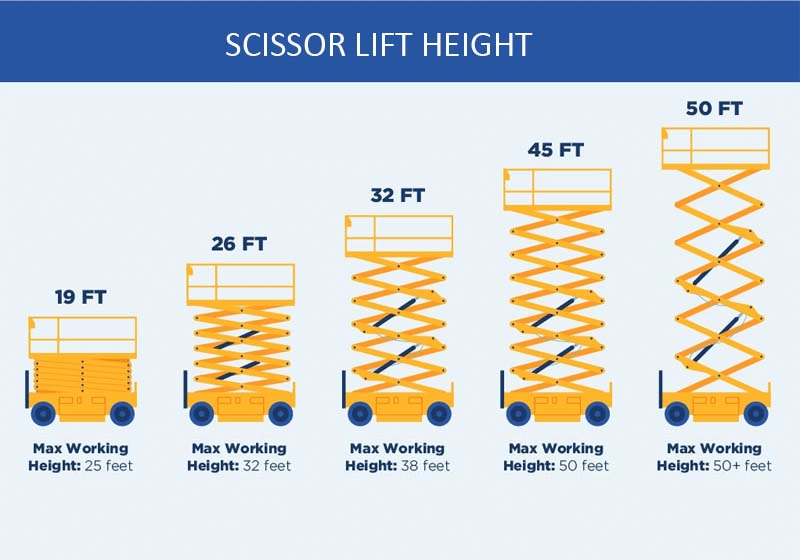

Scissor lifts have many own features. Firstly, it usually adopts a scissor mechanical structure with good stability, which can provide a safe and reliable working platform for workers during high-altitude operations.

Secondly, the lifting process of the scissor lift is relatively smooth, achieved through hydraulic cylinders or other driving systems, and the operation is relatively simple.

Furthermore, some scissor lifts have small volume and light weight, making them easy to transport and install, and can function effectively in spaces with limited space.

The use of scissor lifts is very extensive.

- In the field of architecture, it can be used for high-altitude operations such as building maintenance and decoration;

- In the industrial field, it is suitable for the installation and maintenance of factory equipment;

- In the field of logistics, it can assist in the loading and unloading of goods;

- High altitude equipment maintenance can be carried out in shopping malls, sports venues, and other places.

In short, scissor lifts provide convenient and efficient solutions for various high-altitude work tasks.

OSHA’s general requirements for scissor lifts

OSHA has strict requirements for scissor lifts to ensure the safety of operators.

1. Operators need to receive training and obtain an operating license

Operators must receive professional training, which covers various aspects such as correct operation methods and safety precautions for scissor lifts. This is because as a high-altitude operation equipment, improper operation of scissor lifts may lead to serious consequences.

Only through comprehensive training can operators master the performance and operational skills of the equipment, understand potential risks, and learn how to respond. Obtaining an operating license is a recognition of the skills and knowledge of the operators, ensuring their ability to safely operate scissor lifts in the workplace. As mentioned in the writing material, the purpose of this operating regulation is to ensure the safe operation of scissor lifts, reduce the risk of accidents, and improve work efficiency.

Scope of Application: This operating regulation applies to all personnel who use scissor lifts.

Operating Requirements: Before operating a scissor lift, it is necessary to receive relevant training and obtain an operating permit. Only personnel holding valid operating licenses are allowed to operate scissor lifts.

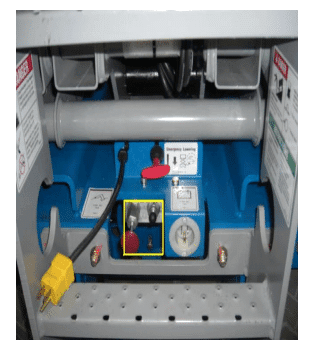

2. Equipment inspection to ensure normal operation and safety requirements

It is crucial to conduct a comprehensive inspection before using a scissor lift. This includes careful inspection of mechanical, hydraulic, electrical and other systems to ensure that the equipment is in good condition. For example, checking for leaks in the hydraulic system, proper functioning of electrical components, and secure mechanical connections.

Only when the equipment is in good condition can the safety of operators be ensured. As mentioned in the safety requirements template for scissor lift trucks, “Before operating, the operator should carefully check whether the various components of the scissor lift truck, such as the hydraulic system, circuit system, and safety devices, are normal.

At the same time, you can also refer to the checklist before operating the scissor lift truck to check the equipment one by one, ensuring that the hydraulic oil is not leaking and the oil level is appropriate, the tire pressure is appropriate and undamaged, the electrical components are undamaged, and the controller is intact. Only by conducting proper equipment inspections can the risk of accidents be effectively reduced.

Personal protective equipment used in scissor lifts

The importance of safety helmets, safety shoes, etc. Explain how these devices protect the operator’s head and feet from injury.

safety helmet

A safety helmet is one of the essential protective equipment for scissor lift operators. In high-altitude operations, there is a risk of objects falling, and safety helmets can effectively protect the operator’s head from the impact of falling objects. Its sturdy shell can disperse impact force and reduce damage to the head. At the same time, the buffer layer inside the safety helmet can further absorb impact energy, providing more comprehensive protection for the head.

Safety shoes

Safety shoes also play a crucial role. During the operation of scissor lifts, operators may face various potential risks of foot injuries, such as heavy objects falling, sharp objects piercing, etc. Safety shoes typically have sturdy soles and uppers that can resist the pressure of heavy objects and punctures from sharp objects. In addition, some safety shoes also have anti slip function, which can provide good grip on damp or smooth surfaces, reducing the risk of slipping for operators.

seat belts

Focus on the requirements for equipping seat belts. Based on the retrieved materials, clarify whether OSHA requires scissor lifts to be equipped with safety belts and the critical role of safety belts in high-altitude operations.

According to the retrieved writing materials, the scissor lift needs to be equipped with a safety belt during use. For example, in the “Precautions for Safety Measures of Scissor type Mobile Lifting Platform – Mobile Sohu Network” section, it is mentioned that “personnel using scissor type mobile lifting platforms must wear full body safety belts.

During the lifting process, the safety belt should be fastened to the platform, basket, or manufacturer’s fastening point. When the scissor type mobile lifting platform reaches the working height, the safety belt is no longer fastened to the scissor type mobile lifting platform, but should be fastened to other structurally reliable fastening points. If there is no reliable fastening point, a steel wire rope should be used to tie it to the steel beam or concrete beam, and the safety belt should be fastened to the steel wire rope loop.

OSHA has strict safety requirements for scissor lifts, and harness play a crucial role in high-altitude operations.

- Firstly, seat belts can prevent operators from accidentally falling during work. Once a fall occurs, the safety belt can be quickly tightened to secure the operator in a safe position, preventing them from falling directly to the ground and greatly reducing the risk of injury or even death.

- Secondly, the correct use of seat belts can provide operators with peace of mind when working at heights, reduce psychological pressure caused by fear of falling, and improve work efficiency and quality.

- In addition, seat belts can also limit the range of movement of operators to a certain extent, making them more stable on the work platform and reducing accidents caused by body shaking.

Key points and precautions for safe operation

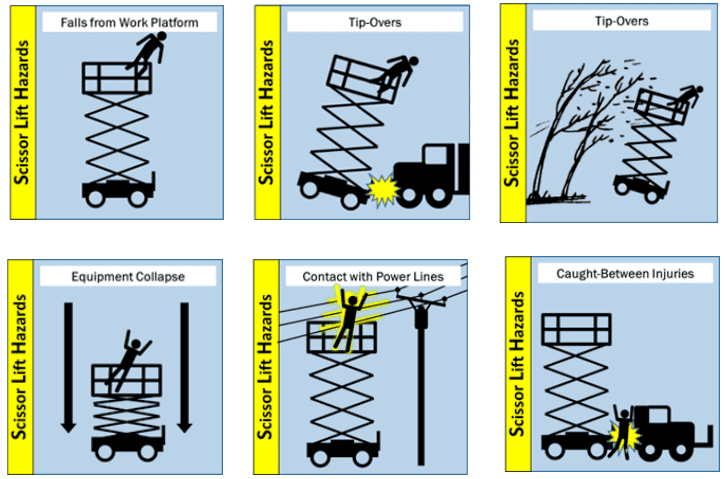

1. Stability during the operation process. Avoid sudden gear changes or emergency stops, ensure smooth operation, and reduce the risk of accidents.

Stability is crucial when operating a scissor lift. Sudden gear changes or emergency stops may cause the equipment to shake, increase the operator’s sense of insecurity, and may also cause damage to the equipment itself. The operator should control the lifting and movement of the equipment slowly and evenly, avoiding hasty operational actions. This can ensure that the equipment remains stable during operation and reduce the risk of items falling or personnel imbalance caused by shaking.

2. Do not overload and maintain balance. Emphasize the potential dangers of overcrowding and imbalance.

Scissor lifts have their specific load-bearing capacity and are strictly prohibited from being used beyond capacity. Overstaffing can cause equipment to bear excessive loads, increasing the probability of equipment failure and accidents. At the same time, it is important to maintain the balance of the equipment during use and avoid one side being too heavy.

If the equipment is unbalanced, it may cause tilting or even tipping over, posing a serious threat to the safety of operators. When loading goods or arranging personnel, the weight should be distributed reasonably to ensure the stability of the center of gravity of the equipment.

3. Prohibited in adverse weather conditions. The scissor lift shall not be used in strong wind, rainstorm, lightning and other weather.

In severe weather conditions such as strong wind, rainstorm, thunder and lightning, it is very dangerous to use the scissor lift. Strong winds may cause the elevator to shake, increasing the risk of tipping over; Rainstorm will make the operating surface wet and slippery, affecting the stability of equipment and the sight of operators; Lightning may pose a risk of electric shock to equipment and personnel.

Therefore, in the event of severe weather, the use of scissor lifts should be immediately stopped, and the equipment should be properly parked to ensure the safe evacuation of personnel from the work area. After severe weather, the equipment should also be checked for damage to ensure its safety performance before use.

OSHA Standards For Scissor Lift Safety Complete Guide

Conclusion

OSHA has strict and detailed safety regulations for scissor lifts, which comprehensively ensure the safety of high-altitude operations from operator training to equipment inspection, to the provision of personal protective equipment and safety operation points.

As a crucial component of personal protective equipment, the importance of harness is self-evident. OSHA explicitly requires scissor lifts to be equipped with safety belts during use. In high-altitude operations, safety belts can effectively prevent operators from accidentally falling and reduce the risk of injury or even death. Once a fall occurs, the safety belt can be quickly tightened to secure the operator in a safe position. At the same time, the correct use of seat belts can make operators work with peace of mind, improve work efficiency and quality, and also limit their range of activities, making them more stable on the work platform.

In order to ensure the safety of high-altitude operations, operators must strictly comply with OSHA regulations. Receive professional training and obtain an operating license, carefully inspect the equipment before use to ensure its normal operation and compliance with safety requirements, correctly wear personal protective equipment such as helmets and safety shoes, and pay special attention to the correct use of seat belts. During the operation, it is important to maintain stability and avoid sudden changes in speed or sudden stops; Do not overload and maintain equipment balance; It is strictly prohibited to use scissor lifts in adverse weather conditions.

Only by strictly adhering to OSHA safety regulations and valuing the role of personal protective equipment such as seat belts, can operators safely carry out high-altitude operations on scissor lifts, reduce accidents, and ensure their own and others’ safety.