OSHA Standards For Scissor Lift Safety Complete Guide

OSHA standards define a scissor lift as a Scaffold but not an aerial lift because the scissor lift is typically fixed, not vehicle-mounted. According to OSHA stands, an aerial lift is something that has the features: “any vehicle-mounted device used to elevate personnel.” So when we talk about scissor lift safety, we should consider it as a scaffold.

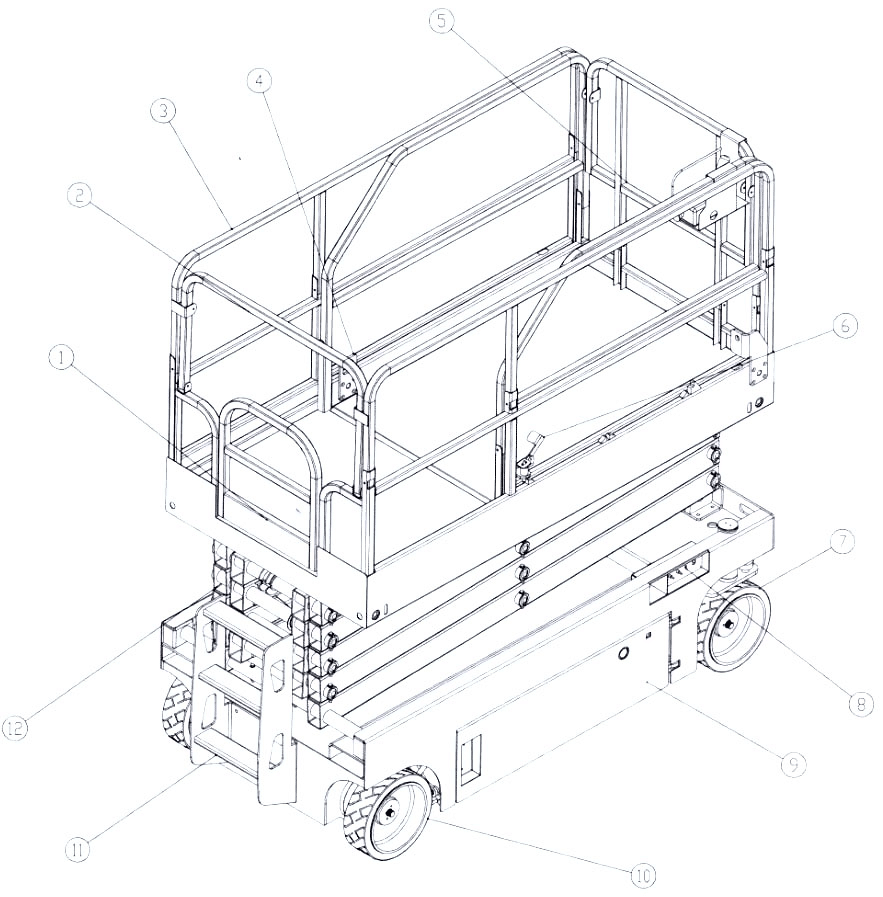

What is a scissor lift?

The scissor lift is a common lifting equipment, mainly composed of an electric motor, oil tank, hydraulic pump, hydraulic cylinder, oil pipe, control valve, oil pipe joint, work platform, etc. It has a rising and lowering platform that’s used to move personnel vertically. During operation, the motor drives the flow of hydraulic oil through a hydraulic pump, causing the piston of the hydraulic cylinder to move up and down, thereby achieving the lifting of the platform.

Read More: The Scissor Lift Guide

What is OSHA?

OSHA is short for “Occupational Safety and Health Administration”. OSHA is below the United States Department of Labor. The administrator for OSHA is the Assistant Secretary of Labor for Occupational Safety and Health. OSHA’s administrator answers to the Secretary of Labor, who is a member of the cabinet of the President of the United States.

OSHA aims to help America’s workers have safe and healthful working conditions free from unlawful retaliation. OSHA carries out its mission by setting and enforcing standards; enforcing anti-retaliation provisions of the OSH Act and other federal whistleblower laws; providing and supporting training, outreach, education, and assistance; and ensuring state OSHA programs are at least as effective as federal OSHA, furthering a national system of worker safety and health protections.

Below are some requirements for OSHA on scissor lift safety:

Guardrails are required for a scissor lift

According to OSHA standard 1926.451, employees must check if a scissor lift has a proper guardrail system in place to prevent workers from falling. If a guardrail system is not in adequate condition, additional fall protection devices must be used during operation, such as a safety harness.

1. To prevent fall accidents, employees should:

Check to see that a guardrail system is in place before working on the scissor lift. Only stand on the work platform and never stand on the guardrails. Keep work within easy reach to avoid leaning away from the scissor lift.

2. Scissor Lifts Must Be Stable Before Operating

High winds, holes, slopes, or getting knocked by another object or machine can cause a scissor lift to be unsteady and fall over. ANSI standard MH-29-2020 states that employees must ensure scissor lifts are stable, protected from any potential hazards.

3. To stabilize a scissor lift:

Select work locations with firm, level surfaces, away from hazards that can cause instability.

Only use outdoor scissor lifts in good weather conditions, with wind speeds that are under 28 miles per hour.

Follow the manufacturer’s instructions for safe movement.

Scissor Lifts Must Be Positioned Correctly

When positioned improperly, scissor lifts can cause crushing and electrocution accidents if they’re tipped over or bumped into another machine. OSHA standards state that you must position scissor lifts carefully in clear zones with plenty of room to operate. It’s especially true when working on electrical lines, where electricity can arc or jump from the power line to the lift or worker.

Here are some things to be aware of when positioning the lift:

- Be watchful when the scissor lift is near obstructions on the job site, like a fixed object, moving vehicle, or another piece of equipment.

- Implement traffic control measures to prevent workers and vehicles from getting too close while the lift is in use.

- Select work locations that are at least 10 feet away from power sources (like power lines, transformers, other electrical sources, and so on) and that don’t pose other overhead hazards (like other utilities, branches, door frames, overhangs, and so on).

Regularly Maintained is needed for a scissor lift

According to OSHA, to prevent any of the machine’s lifting mechanisms from collapsing or malfunctioning, scissor lifts should be regularly inspected. This ensures all parts of the scissor lift are working properly and are in good repair.

To make sure your scissor lift is well-maintained and safe to use:

- Test and inspect controls and components before each use.

- Ensure that guardrail systems are in good working condition.

- Verify that brakes, once set, will hold the scissor lift in position.

Scissor Lift Safety Tips according to OSHA

In addition to OSHA and ANSI guidelines, there are other safe work practices to keep in mind. Here is some additional scissor lift safety tips to incorporate into your lift safety training and keep your workers safe.

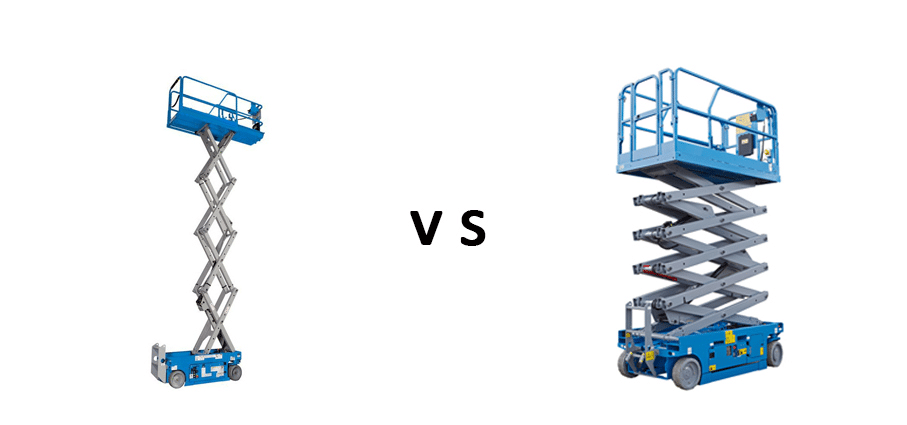

Select the Correct Type of Scissor Lift

Scissor lifts come in a variety of different types, such as electric, rough terrain, pneumatic, diesel, or hydraulic. It’s important to find the right scissor lift for your specific worksite, not only to ensure it does what you need but also to keep your scissor lift operators safe.

If you work outdoors, a rough terrain lift is probably ideal. If you’re doing indoor maintenance, an electric lift might be your best bet.

Check the Manufacturer’s Load and Reach Capacity

Before operating the scissor lift, be sure to check the manufacturer’s instructions for details like weight limits, load rating, and reach limits. Exceeding your lift’s load or reach capacity can cause it to become unstable or tip over.

Evaluate the Job Site’s Environment and Conditions

Before you begin work, examine your work area’s conditions to see what safety hazards you might run into. For outdoor worksites, this could include holes, pits, uneven terrain, and weather conditions. For indoor worksites, this could include overhead hazards, bumps, or other obstructions.

Scissor Lift Safety Tips and Rules During Operation

- Check the scissor lift before operation. If the scissor lift fails the pre-operation inspection, report the issue to the supervisor. Do not attempt to repair the scissor lift on your own.

- Wear appropriate personal protective equipment (i.e. safety helmet, goggles, gloves) during operation.

- Keep a safe distance from wires and equipment. It has electrical hazards and may collide with you at heights.

- Do not exceed the manufacturer’s rated platform capacity. Carefully read the manual and check the load chart. It has more detailed information about load capacity and how to balance loads at high altitudes.

- Materials shall not be transported on platform railings without the manufacturer’s approval. Check the manual provided by the manufacturer. It contains all the details of platform rules.

- Do not sit, stand, or climb the guardrails of elevated work platforms, or use wooden boards, ladders, or other equipment to achieve higher work heights. Any slipping or tipping can lead to serious accidents.

- Do not allow anyone to work, walk, or stand under an elevated boom or platform. This is the main cause of any fall accident.

- Pay attention to obstacles when driving The scissor lifts or moving platforms. Check for hazardous situations, uneven surfaces, and overhead obstacles such as wires in the work area. Report any unsafe situations to the supervisor before continuing the task using the scissor lift.

- When driving the scissor lift, keep non-operators at least 6 feet away from the machine.

- Do not forcefully strike the control switch or lever in the opposite direction through neutral. Always return the switch to neutral and stop; Then move the switch to the desired position.

- Do not use the scissor lift as a crane or use it to push or pull other objects. It can lead to structural damage and high maintenance costs.

- Do not place or support the suspended basket of the aerial lift on any structure or against any structure.

- When working on an aerial lift, do not tie the seat belt to adjacent poles, structures, or equipment.

- Before using the scissor lift on a slope, please use the braking system. If it is safe to do so, please block the wheels of the scissor lift.

- When the suspension rod is in the raised working position and the worker is moving the high-altitude The scissor lift in the basket, ensure that all control devices have been tested and operate normally.

As a common lifting equipment, scissor lifts have high efficiency and flexibility, but safety precautions and operational requirements need to be paid attention to during use to ensure the personal safety of workers and the normal operation of the equipment. Therefore, strict training and inspection must be conducted before use to ensure that the equipment is intact and operates in accordance with the operating procedures and precautions.