What is the scissor lift?

The scissor lift is one type of high aerial work platform man lift and widely used on commonly interior work jobs like ceiling construction, sign hanging, lifting people, materials, and other maintenance projects. Compare to a boom lift, scissor-man lifts have a lower platform height. The maximum height of a scissor lift is normally between 14 ft to 59ft.

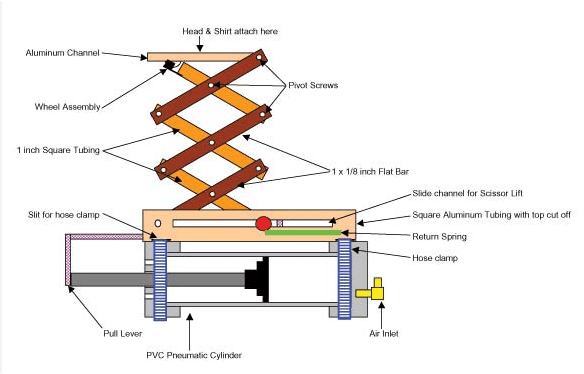

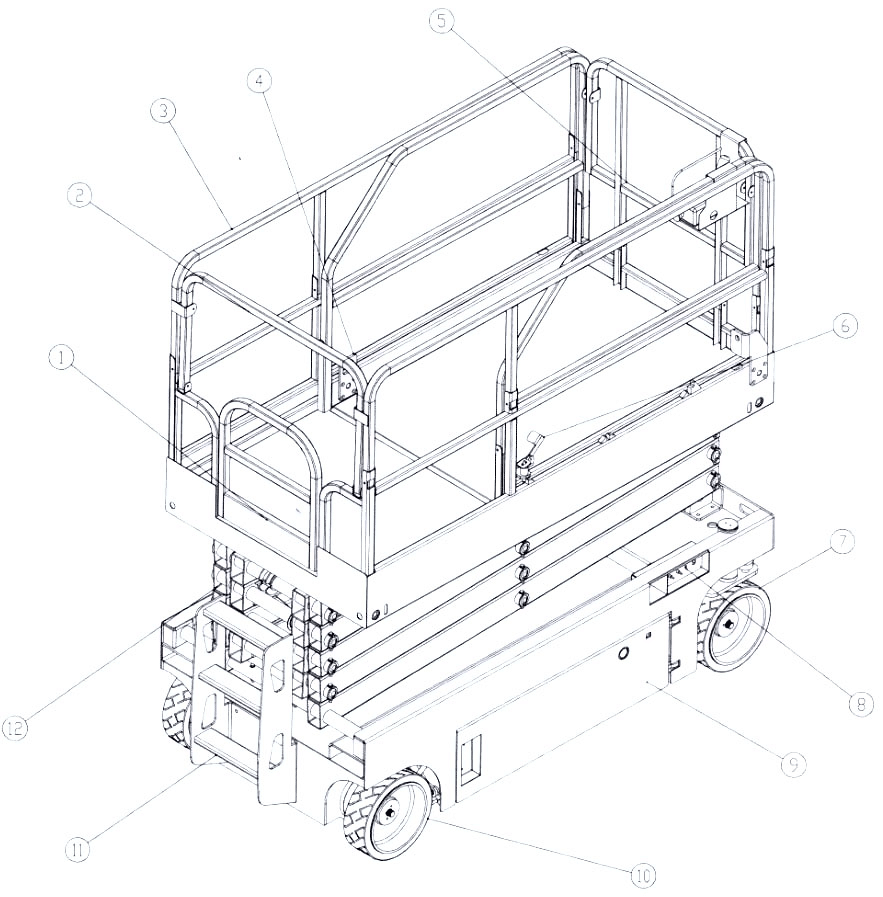

It is like a “scissor” which could move up and down with crisscrossed beams. This is why a scissor lift get its name from their lifting mechanism design — a stack of crossed tubes that work in a scissor-like fashion when the platform is raised and lowered. The OSHA classify a scissor lift as a mobile-supported scaffold work platforms but not aerial lifts because the scissor lift could not move horizontally, it could only move vertically. (up and down).

A scissor lift is required because it could help to enhance the production ability and could easily to complete any task such as elevated workspaces, including sign hanging, ceiling work, light fixture installation, or maintenance tasks. Sometimes, scissor lift could also use for outdoor projects such as bricklaying, tree trimming, or working on power lines. This article will introduce the concept, application, types, safety, and buying guidance for the scissor lifts.

Concept of the Scissor Lift

Scissor lift is a widely used specialized equipment for aerial working platform operations. Its scissors mechanical structure provides high stability for the lifting platform, with a wide working platform and high load-bearing capacity, making the high-altitude operation range larger and suitable for multiple people to work simultaneously. It makes work efficiency higher and safety more secure.

Scissor lift is a type of self-propelled man lift which is widely used in construction and facility maintenance applications designed to elevate workers and their tools to working heights with the value from 5.9 m (19 ft) to 17.9 (59 ft).

Benefits of using a scissor lift

Surely a scissor lift could help your jobs. It has many advantages in using a scissor lift indoor and outdoor.

- A scissor lift can enhance the productive ability and great for indoor and outdoor jobs,

- There many types of scissor lifts from 19 ft to 59 ft which could use in different height.

- The scissor lifts could help you to get more platform space and lift capacity. All the scissor lifts have a platform extension that slides out one end of the deck for additional space and outreach.

- The scissor man lifts offer big power to drive around the worksite and climb ramps. In the stowed position, Tacman scissor lifts can climb grades ranging from 25 to 55%.

- The scissor man lifts could perform repetitive jobs, the operator can easily drive between tasks.

- A scissor lift can help you to do jobs in special worksite conditions.

What is a scissor lift used for? (Applications)

When talking about the application or usage of the scissor lift, it refers to a lot of work environments not only limit in construction but also suitable for indoor worksites.It is widely used in elevated work platforms (EWP).

Instead of the ladder, tower, or scaffolding

One of the biggest advantages of using a scissor lift is that it is a perfect alternative to a ladder, tower, or scaffolding. Due to its “scissor” design, this man lift could move up and down easily and safely. The worker could stand on the platform which reduces the risk of dropping down and injury.

Easy for Ceiling Work

Public places such as Government offices, libraries, Schools, hospitals, hotels, factories, and other buildings with high ceilings have a large requirement for scissor lifts for elevated or lifting tasks. The scissor lifts could help to lift the workers to a tall place to install or replace overhead lamps, cables, and HVAC pipes. Of course, the scissor lifts could also help people paint, construct, or repair damage on ceilings or tall walls.

Repairing Power Cables

Compared to ladders, a scissor lift has more reliable stability and safety, it is a perfect option for fixing and maintaining power lines. By moving up and down the working method, the scissor lift work platform lifts workers and tools to the power lines, where they can make fixes.

Hanging Signs and billboard

In some construction areas, the worker needs to hang warning signs to alarm people that the area is dangerous. For example, a Scissor lift hangs a sign to tell people there is construction in front. For some shops, they need to hang the billboard to show their business and attract customers, the scissor lift will help them to finish the job safely.

Maintenance Repairs

No matter how difficult the repair or maintenance job is, the scissors lifts belong to an aerial work platform can complete it perfectly. With a tall lift ability, the factory and industrial workers are able to check large machinery; Ordinary engineers could use them to check the lamps and cables. HVAC engineers may use them to inspect pipes or A/C units, and maintenance workers may use them to repair ceiling damage.

A good tool in Warehousing organization

Are you worry about using a ladder to tidy so many goods and materials in a warehouse? Using a scissor lift will not have this concern. Scissor lifts offer a safe way to simplify inventory processes, including loading and unloading pallets and lifting and retrieving heavy goods from shelves. Not only limited to tidying the goods and shelves, the worker in a warehouse could also use them to change lamps and cables.

Recording and Filming Events

To get the best filming results, using a scissor lift is a good choice. Imagine that, a scissor lifts the camera in a tall attitude, you will get a full view of the film. Artists may also use them when they need a boost for big projects like high murals or tall sculptures.

Build a house

For those high buildings, a boom lift may help more. But if for building a personal villa which is normally 3 or 4 floors, the scissor lift will show its skills. No matter the building, installing windows, air conditioning, or lifting materials to upper floors, the scissor lift will surely help you a lot.

Features of the Scissor Lift

The scissor lift is mainly used in the logistics industry, production lines, and for lifting and unloading goods from basement to floors. It can also be used for lifting stages, lifting operation platforms, etc. The product has a stable structure, low failure rate, reliable operation, safety and efficiency, and simple and convenient maintenance.

Fixed scissor lifts can be equipped with accessory devices according to usage requirements, and can be combined in any combination, such as safety protection equipments, electrical control methods, working platform forms, power forms, walking drive mechanisms, etc.

When using a scissor lifts, attention should be paid to the correct selection of various configurations, which can maximize the functionality of the lifting platform and achieve the best usage effect.

Types of the Scissor Lift

Scissor lifts types can be different depends on the method of Classifications. Here are a list on different types of the scissor lifts due to the classifications.

| Classifications | Power | Working or platform height | Conditions | Technology | Brands |

| Scissor lift type | From power side, there are electric and rough-terrain scissor lifts | From the height side, there are 19ft, 26ft, 40ft, 50ft… scissor lift | From the condition side, there are brand new and used scissor lift | From the technology, there are fixed, Self Propelled, Truck Mounted, and Manual Traction scissor lifts | From brands side, there are JLG, Genie, Dingli, Skyjack, Sinoboom and other brands scissor lifts. |

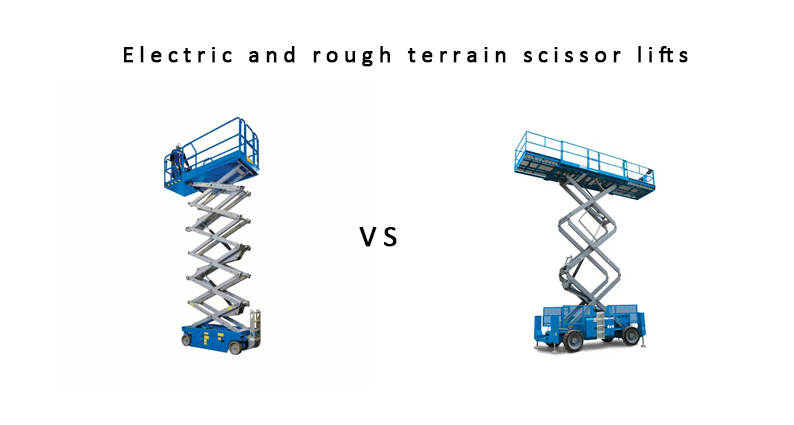

From the power consideration, It can divided into electric(battery-powered) and rough-terrain(engine-powered). These two types of scissor lifts can lift 2 to 4 workers to elevated heights, but these are the main similarities. Now we will explain the differences between these two types of scissor lifts.

Electric scissor lift

Electric scissor lift has the features: quiet, maneuverable machines with zero emissions, electric scissor lifts excel in indoor environments with level surfaces. They lend themselves to projects like window cleaning, fixture installation, and building repairs.

Rough-terrain scissor lift

Due to the big power and ability to work in tough terrains, rough terrain scissor lifts make a great choice for outdoor industrial and construction applications. If your project involves uneven surfaces or off-road navigation, these four-wheel-drive models fit the bill.

specification consideration

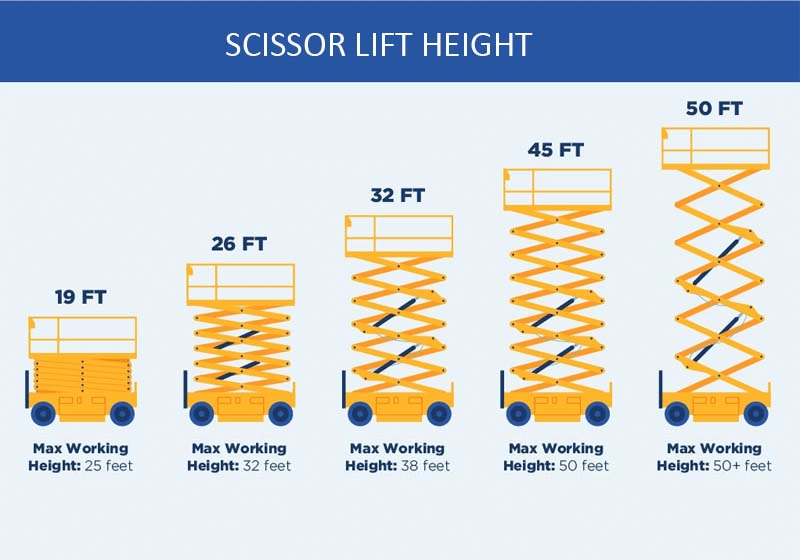

From the specification (platform height) consideration, There are 19 ft, 26ft, 30ft, 32ft, 38ft, 40ft, 45ft, 50ft and other size scissor lifts.

technology consideration

From the technology consideration, Scissor lift types are divided into: fixed scissor type scissors, mobile scissors, self-propelled scissors, truck mounted scissors, manual traction scissors, and specialized scissors for carrying goods.

brand consideration

There are JLG, Genie, Dingli, Sinoboom, Skyjack and other brands scissor lifts. They all have high power and could work in different environments.

condition consideration

There are brand new scissor lifts and used scissor lifts. We offer a full solution for buying or renting new and used scissor lifts.

How to select a good Scissor Lift?

With the development of social science and technology, scissor lifts in aerial working platforms have been popularized in every corner of social life, and their application is becoming more and more widespread. Whether it is in construction, civil engineering, or people’s daily lives, scissor lift are indispensable. Many businesses seize this opportunity and invest in building factories.

Scissor lifts companies have sprung up in major industrial cities like bamboo shoots after rain, The market for scissor lifts is extremely hot, with supply exceeding demand. From a side view, it can be seen that the rapid development of society has driven the development of the entire industry and people’s demand.

However, as a buyer, how to choose a good scissor-type aerial work platform from the abundant company products has become an important topic today.

When choosing a scissor lifts, one should not blindly choose it. Adequate market research and on-site inspections should be conducted to determine the company’s scale and reputation. This is the first and foremost requirement. Many small-scale enterprises in the market are cutting corners to seek violence, which greatly reduces the quality of their lifting products. Although they may sell them very cheaply, this type of machinery does not last long and has a high degree of danger. Therefore, as a buyer, one should not indulge in a small discount on price and end up with greater regret.

Based on the information you have researched, choosing a cost-effective scissor lifts should be based on its technical parameters, practicality, and versatility. There are usually many types of lifting machinery, including (vehicle mounted, fixed, hydraulic, tractions scissor type, etc.), each with slightly different technical parameters and uses. However, many functions are similar. Therefore, as a customer, you should make purposeful purchases, What do you want to do when buying a lifting mechanism, and which type of lifting mechanism can meet your needs and has multiple uses.

The last point is that after the equipment arrives, during the unpacking acceptance, it is necessary to check whether the random technical information is complete, whether the random accessories, tools, and accessories are consistent with the list, whether the equipment and accessories are damaged or defective, and make a good record of the unpacking acceptance.

Below are important factors when you are choosing a good scissor lift:

1. Budget

We have to say the budget is one of the most important factors in deciding which scissor lift to choose. If you have a large budget, you could consider brand new and famous brand scissor lifts for your business, such as the JLG and Genie new scissor lifts. Otherwise, a secondhand or used scissor lift will be your best choice. If you have very limited budget you could consider year 2002 to 2018 using scissor lift for your business.

2. Working height

Selecting the right working height for your business is very important. A low working height may not meet your job requirements. A high working height may cost you more money. With scissor lift heights typically ranging from 19 to 59 feet, you have several options to choose from.

3. Platform width

Think about it, a scissor lift with an over-width may not be possible to enter the door! You must find a best platform width for your indoor jobs. While platforms come in standard sizes, you can choose an extended platform. If your job requires larger platforms, make sure to adjust your calculations accordingly to keep the loads balanced.

4. Condition of the environment and terrain

That is why there are electric and rough terrain scissor lifts. If you need a quiet working environment, select the electrical man lift, it almost has no noise, no emissions and non-marking tires. working indoors. If you need the scissor lift to drive on a tough terrain ground, select the 4WD four-wheel drive engine power rough terrain model.

5. Load capacity:

The load capacity depends on how many workers and how heavy materials your scissor lift could load in one time. If you plan to carry multiple workers or heavy loads, you may want to look for a heavy-duty scissor lift. Otherwise, a mini or medium load capacity will meet your demands.

6. Type of job task:

It is not wise to buy an unfit specifications scissor lift for the task you have. Ask yourself what you need to perform. Ceiling work may require a higher lift platform while warehouse work might prioritize maneuverability over height.

7. Brands and supplier

It is important to select a reliable brand scissor lift such as JLG and Genie. Check if your supplier of the man lift is professional and reliable.

Operating procedures and regulations of the Scissor Lifts

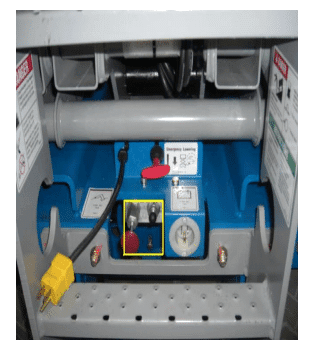

- Abnormal noise;

- The oil temperature rises rapidly;

- Abnormal oil cylinder pressure and return oil pressure;

- Oil leakage in the oil circuit;

- When pressing the ‘up’ or ‘down’ button, or pushing the ‘p’ or ‘down’ manual valve, the workbench does not move.

How High Can a Scissor Lift Go?

For most of the scissor lifts in the market, they can reach the height from 16 to 50 feet off the ground. Compact scissor lift models are lighter but can hold less, while bigger models have less maneuverability but a higher weight capacity. For example, a 50-foot scissor lift can lift up to 2,350 pounds.

Boom lifts VS Scissor lifts

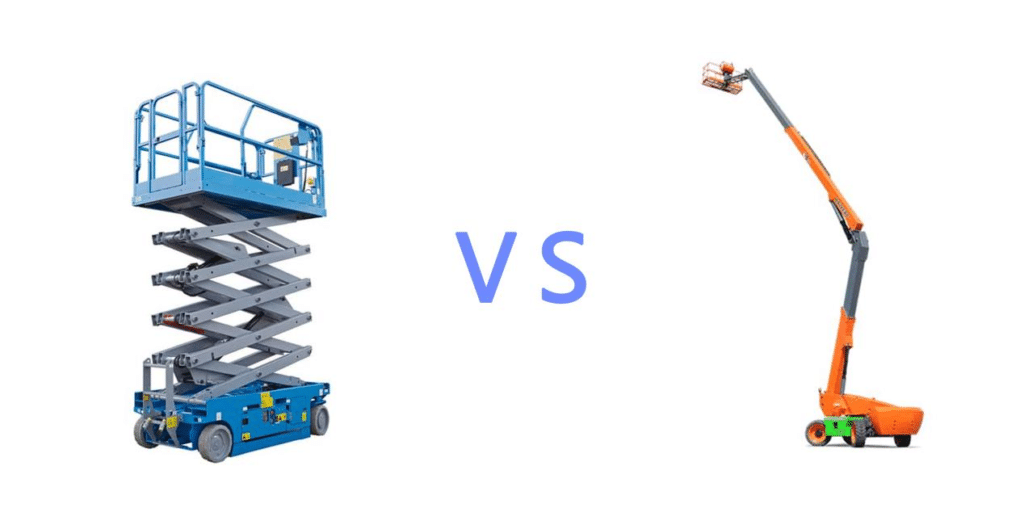

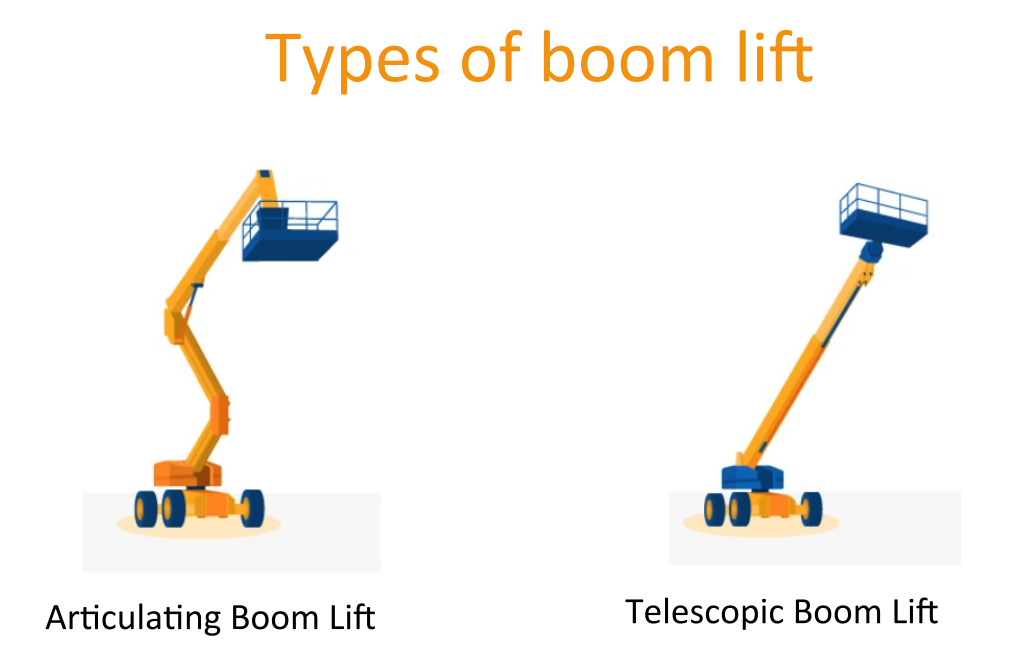

Boom lifts and scissor lifts are two types of tools for entering in elevated work areas. A scissor lift could only go up and down vertically, while a boom lift could go vertically and horizontally. The nature of your project and the situations of your worksite help you to decide which lifts to select.

| Type | Movement | Reach height | Platform capacity | Terrain | Used equipment price | Rental price |

| Boom lifts | vertically and horizontally at any angel | Up to 50 feet | Up to 2250lbs | Uneven, rocky, or flat surfaces | USD $19,000 to USD $ 500,000 | USD $1,500 to USD $ 9,000 |

| Scissor lifts | Vertically up and down | Up to 260 feet | Up to 500 lbs | Smooth, flat, or uneven surfaces | USD $3,000 to USD $15,000 | USD $300 to USD $ 1,200 |

Do I Need Certification to Use a Scissor Lift?

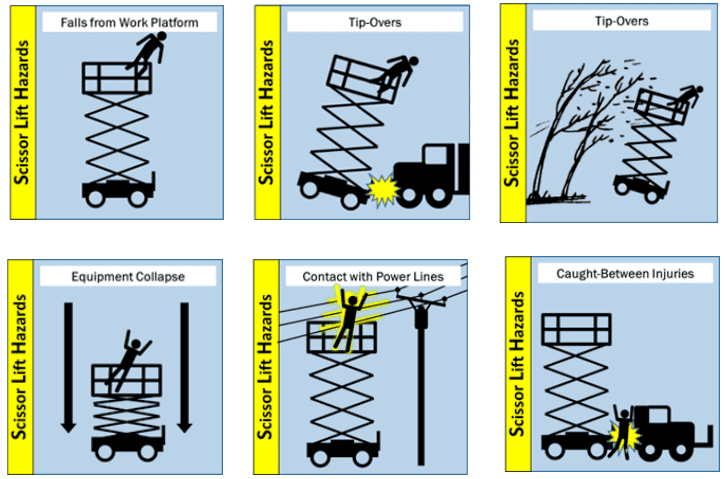

One thing we should note is that scissor lift is a professional equipment, the operators must learn on how to safely operate scissor lifts, means the operator must be well trained. There is no requirements for an official certification. Under OSHA guidelines, employers must train employees on how to work safely with or near scissor lifts, how to handle materials on the lift, and what worksite hazards they might encounter while operating the lift.

Although stopping short of requiring certification, the agency stipulates that only employers should only permit trained personnel to use a scissor lift. This makes employers largely responsible for ensuring that workers operate lifts safely.

OSHA also provides a one-hour scissor lift training course online that covers key topics such as safety procedures, applicable OSHA standards, the importance of inspections, and precautions for preventing falls, tips, electrocution, and other common hazards.