Boom Lift: Definition, Types and working principle

Concept of Boom Lift

Boom Lift is a common lifting equipment in higher height aerial working platform solutions between telescopic boom lift & articulated boom lift, mainly composed of the following parts:

The above are the main components of the boom. The different models and uses of the boom may vary, but the overall structure and composition are similar. The performance and quality of the boom depend on the design and manufacturing quality of each part.

Therefore, when purchasing and using the boom, it is necessary to pay attention to selecting the appropriate model and brand, and carry out regular maintenance and repair to ensure its safe and reliable operation.

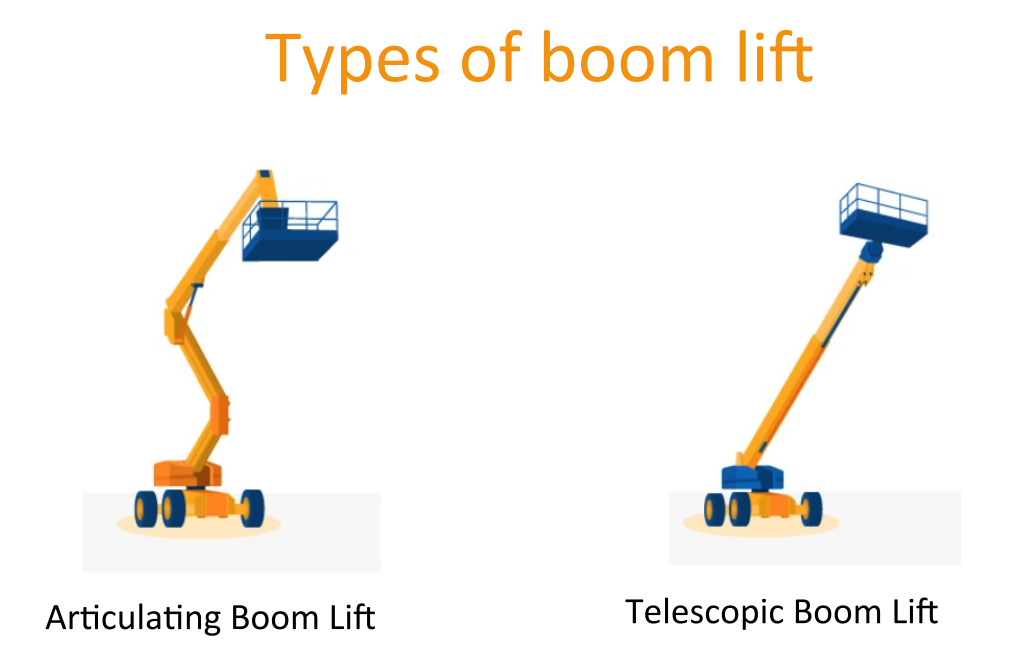

Boom Lift Classifications (Types)

There are two types of boom lifts popular in the market, telescopic and articulated. They are both can be used for indoor and outdoor jobs.

Telescopic Boom Lift

A telescopic boom is a multifunctional machinery mainly used for lifting, handling, stacking, transportation and other operations. It can complete various tasks that conventional forklifts and cranes cannot complete. According to their different functions and properties, straight-arm vehicles are mainly divided into four categories: agricultural, industrial, mining, and construction.

Structure and working principle

A Telescopic boom lift mainly consists of a chassis, a turntable, a body, and an arm. There is a rotating part in the center of the fuselage, and the arms consist of four smaller inner telescopic arms and a larger outer telescopic arm. The entire system can rotate 360 degrees to reach key job positions. During various tasks, the straight arm vehicle adjusts the length of the arm accordingly to achieve different functions.

The Telescopic Boom Lift mainly adopts an oil pressure forced telescopic structure, which has a large bearing capacity and stability. The main working principle is to use the boom extension of the crane to achieve the effect of lifting heavy objects.

Application field

Telescopic Boom Lift have the characteristics of compact structure, flexibility, simple operation, and high work efficiency, so they are widely used in logistics centers, warehouses, stations, docks, airports, mines, construction sites, and so on. At the same time, it can also be used for planting, harvesting, transportation and other operations in the agricultural field.

Advantages and disadvantages

The Telescopic Boom Lift is easy to operate, has stable performance, strong load-bearing capacity, and is not prone to overturning. At the same time, it can be extended and retracted according to work needs, with extremely high flexibility. But there are also some drawbacks, such as being too heavy on one side of the fuselage, which can easily cause instability of the center of gravity and have a significant impact on the ground, making it unsuitable for irregular terrain.

In summary, a Telescopic Boom Lift is a multifunctional mechanical device with a wide range of applications and good performance. However, it is also necessary to pay attention to its disadvantages and choose and use it based on actual situations.

Articulated Boom Lift

As an important component commonly used in modern Articulated Boom Lift, it is a key tool for lifting heavy objects. It usually consists of one or more curved arms, an electric motor, a set of reducers, and a set of gear profiles. The operation of the Articulated Boom Lift requires strict operating procedures to ensure safety and efficiency.

Structure and working principle

Articulating boom lifts usually consist of one or more curved arms equipped with an electric motor, reducer and gear system. Strict operating procedures are required during operation to ensure safety and efficiency.

The operator first checks the overall condition of the lift, including the operation of the arms, gears, motors and reducers. Confirm that the connection to the main body is tight and reliable to ensure safe lifting. Operators also need to check the weight limit of the lift to avoid overloading, which could lead to equipment damage or dangerous operation. After starting the motor, it should be gradually accelerated to ensure smooth and error-free lifting operation, and the height and direction of the lift should be adjusted as needed.

Application field

Ideal for hard-to-reach work areas, articulating boom lifts offer a multi-jointed arm structure, making them useful on construction sites, warehouses, factories, gardens, and environments that require working at heights in tight spaces. In addition, they are also suitable for urban construction, road construction, garbage cleaning and other scenarios.

Advantages and disadvantages

Difference between Telescopic Boom Lift & Articulated Boom Lift

The main difference between the Telescopic Boom Lift & Articulated Boom Lift lies in the number and length of arms, working height, working radius, and working field.

Overall, both Telescopic Boom Lift & Articulated Boom Lift have their own characteristics and usage scenarios, and suitable vehicle models need to be selected based on specific operational requirements.

How to choose Telescopic Boom Lift & Articulated Boom Lift

When choosing between a Telescopic Boom Lift and an Articulated Boom Lift, you should consider the following key factors:

1. Working height and radius

If higher operating heights and larger operating radii are required, telescopic boom lifts may be a better choice as they can typically reach higher heights and cover a wider horizontal range.

2. Working environment

Straight arm(telescopic) boom lifts are suitable for outdoor operations, such as construction sites, shipyards and other environments that require efficiency and reliability. Articulating boom lifts are more suitable for indoor work or use in narrow spaces.

3. Ground conditions

If the working ground has a strong carrying capacity, you can choose a telescopic boom lift. If the floor capacity is limited or uneven, an articulated boom lift may be more suitable.

4. Speed and efficiency:

If the job requires rapid lifting and lowering, a straight boom lift will usually lift faster than a articulated boom lift.

5. Equipment Cost and Maintenance:

The purchase price and maintenance cost of telescopic boom lifts are usually higher, while the purchase price and maintenance costs of articulated boom lifts are lower due to their relatively simple structure.

6. Specific application scenarios:

Depending on the specific job needs, such as urban construction, road construction, garbage removal, etc., an articulatied arm lift may be more suitable. For operations that require larger spans and excavation depths, such as large-scale infrastructure construction and rural land consolidation, telescopic boom lifts may be more suitable.

7. Energy type

Articulated boom lifts are available in lithium battery and diesel power types, while telescopic boom lifts are usually diesel powered because outdoor operations have lower requirements for noise and air pollution.

Take these factors into consideration and select the most suitable lift model based on specific operating needs and conditions.