What Is a Limit Switch On lifts & How Does it Works?

Definition Of Limit Switch

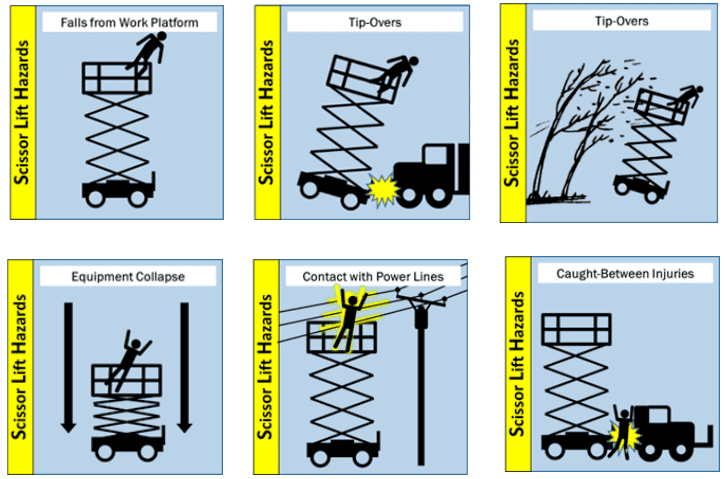

For scissor lifts and boom lifts, the limit switch plays an important role in controlling the working in a limited position which ensures safety and stability during the operation.

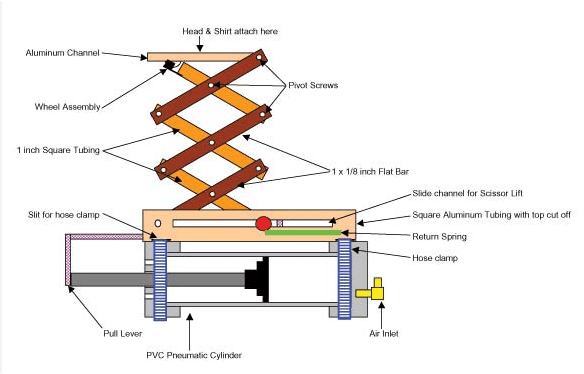

Scissor lifts have become powerful assistants for many construction sites due to their unique structure and flexible operation methods.

For electrical engineering, a limit switch is a switch operated by the motion of a machine part or the presence of an object. A limit switch can be used for controlling machinery as part of a control system, as a safety interlock, or as a counter enumerating objects passing a point. Our limit switches work perfectly on JLG, Genie, Skyjack, Snorkel, MEC and other brands lifts. They are reliable and durable, making them suitable and safe for various uses.

How does the limit switch work on scissor lift and boom lift?

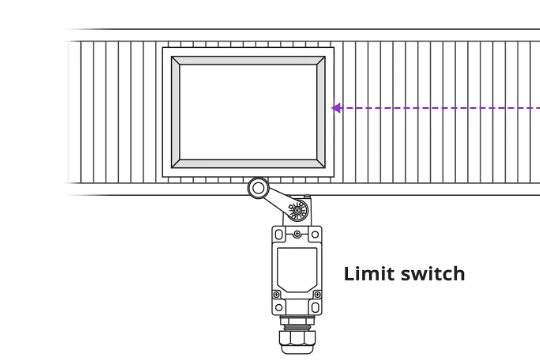

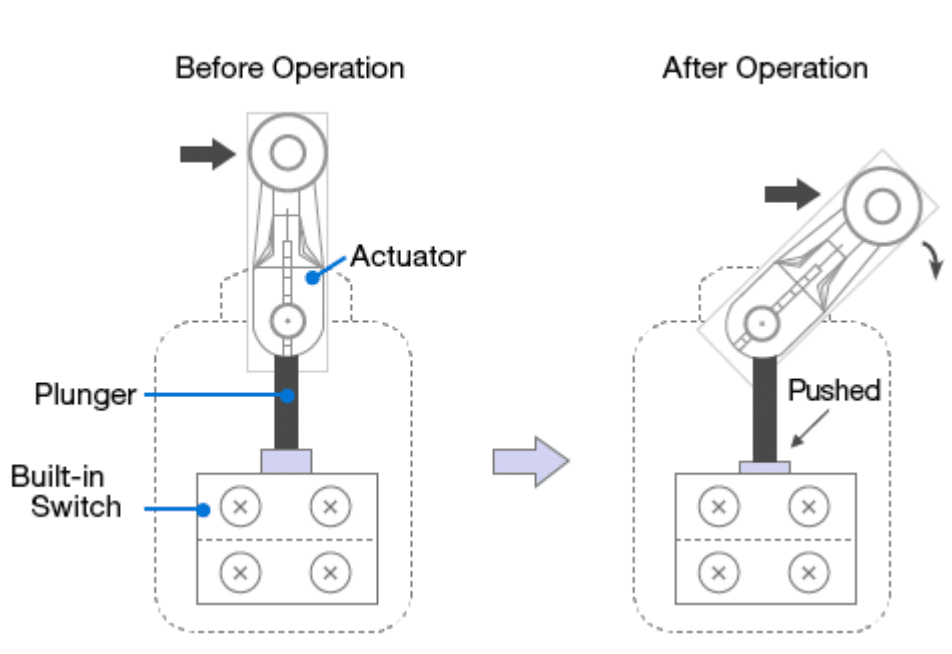

The limit switch of a scissor lift is an electrical component installed on the scissor lift. It monitors and controls the movement range and working status of the scissor lift through mechanical triggering.

Simply put, when a certain moving part of the scissor lift, such as the lifting and lowering of the work platform, the extension and retraction of the telescopic arm, etc., reaches a predetermined limit position, the corresponding mechanical structure will touch the limit switch.

Once triggered, the limit switch will immediately send an electrical signal to the control system. After receiving the signal, the control system will take corresponding actions, such as stopping the operation of the drive motor, locking relevant moving parts, or triggering alarm devices, to prevent further actions of the scissor lift beyond the safe range.

This process is like a diligent ‘security guard’, always guarding the safe operation of the scissor lift.

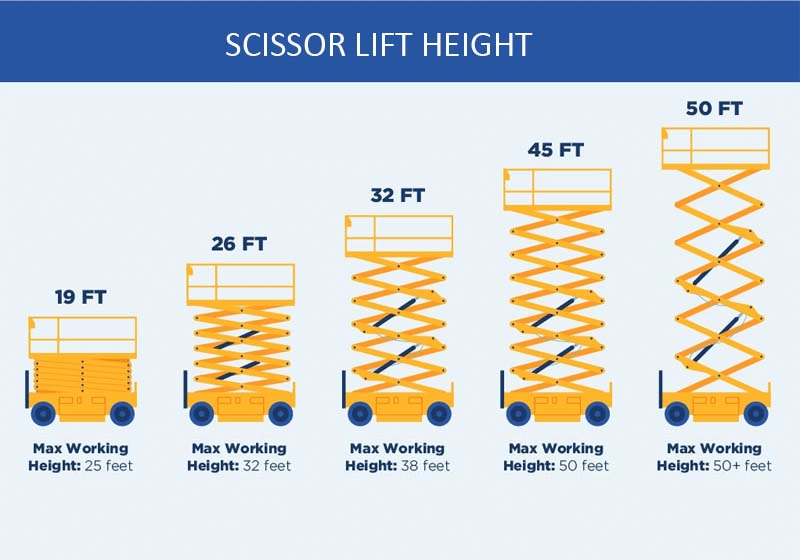

Taking the lifting function of a scissor lift as an example, when the work platform reaches the set maximum height, the lifting action triggers the limit switch.

At this time, the control system will immediately stop the platform from continuing to rise, avoiding collisions with obstacles above, or dangerous situations such as equipment imbalance and tipping due to excessive lifting.

Similarly, during the platform descent process, when the minimum safe height is reached, the limit switch will also function to prevent excessive platform descent from causing damage to personnel and equipment.

How does the limit switch ensure the safety?

In addition to ensuring the personal safety of the operators, the limit switch of the scissor lift is also of great significance for the protection of the equipment itself.

Frequent out-of-range operation not only accelerates equipment wear and aging, and reduces its service life, but may also cause serious mechanical failures and damage.

By accurately and timely limiting the range of motion of the scissor lift, limit switches can effectively reduce unnecessary wear and maintenance costs, and improve the reliability and stability of the equipment.

Types of the limit switches

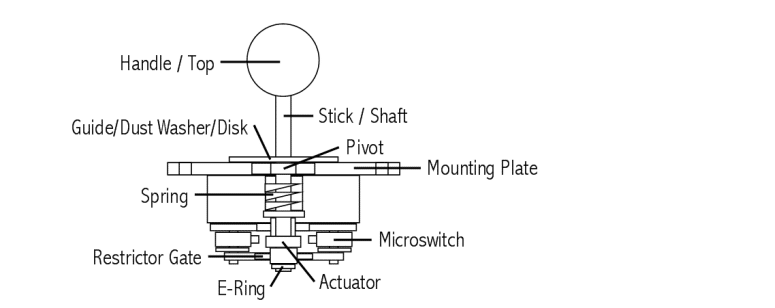

In practical applications, there are various types of limit switches for scissor lifts, including contact limit switches and non-contact limit switches.

Contact type limit switches

Contact-type limit switches are triggered by mechanical contact, with a relatively simple structure and low cost. However, in long-term use, their performance and reliability are easily affected by factors such as wear and fatigue.

Non-contact limit switches

Non-contact limit switches, such as photoelectric, inductive, capacitive, etc., trigger by sensing the presence or change of the target object. They have the advantages of fast response speed, long lifespan, and no mechanical wear, but the cost is relatively high.

Regardless of the type of scissor lift limit switch, regular inspection, maintenance, and calibration are required to ensure its performance is always in good condition. Before each use of scissors, the operator should also carefully check the working condition of the limit switch to ensure that it can function properly. Only in this way can we truly nip safety hazards in the bud and allow the scissor lift to operate on a safe and efficient track.

Common Limit Switch Brands

Genie limit switches:

JLG limit switches:

Haulotte limit switches:

How To Replace A Limit Switch For Genie Boom Lifts And Scissor Lifts?

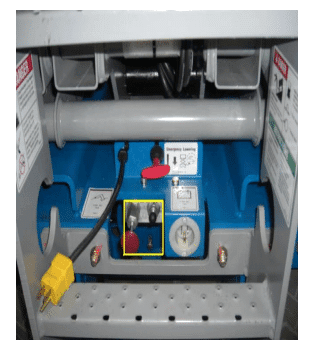

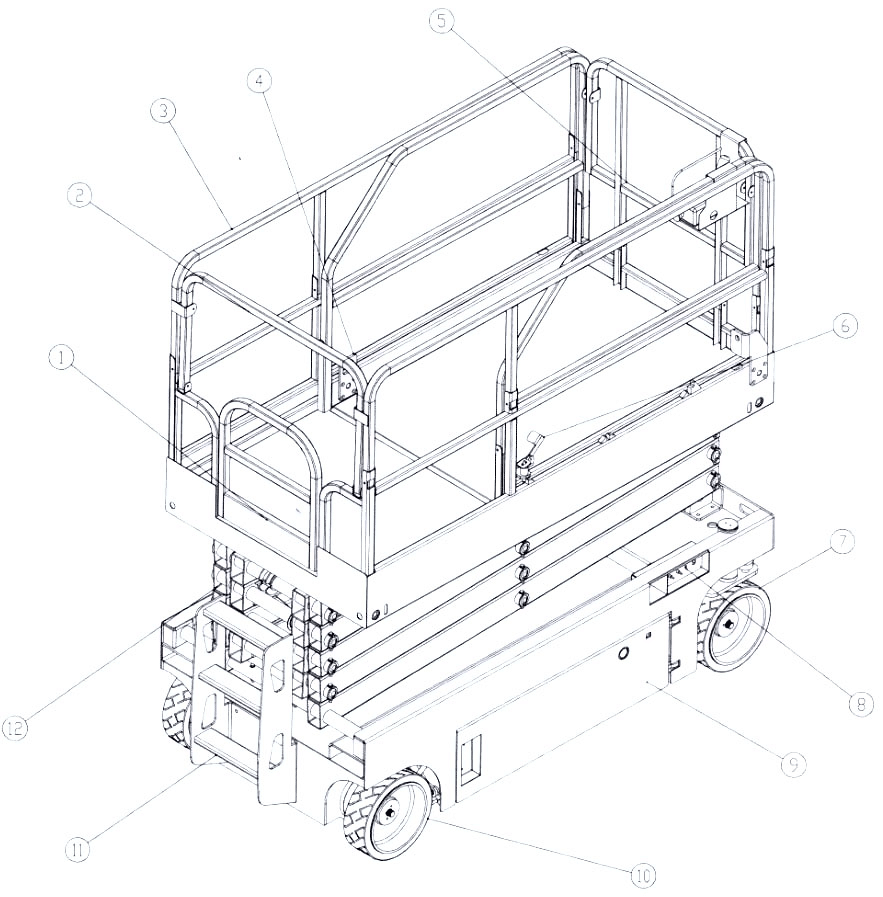

- Step 1: Remove the Access Cover.

- Step 2: Locate the Limit Switch.

- Step 3: Conduct a Voltage Test.

- Step 4: Turn Off the Power.

- Step 5: Disconnect the Switch.

- Step 6: Unscrew and Remove the Switch.

- Step 7: Install a New Switch.

- Step 8: Replace the Furnace Cover.

- Step 9: Test the machine function after replacing the limit switch.