How to transport a scissor lift?

Scissor lifts can quickly transport goods from one place to another, reducing the time and cost of manual. Especially in warehouses, production lines, and other places, scissor lifts can easily transport heavy objects, providing strong support for the production and operation of enterprises.

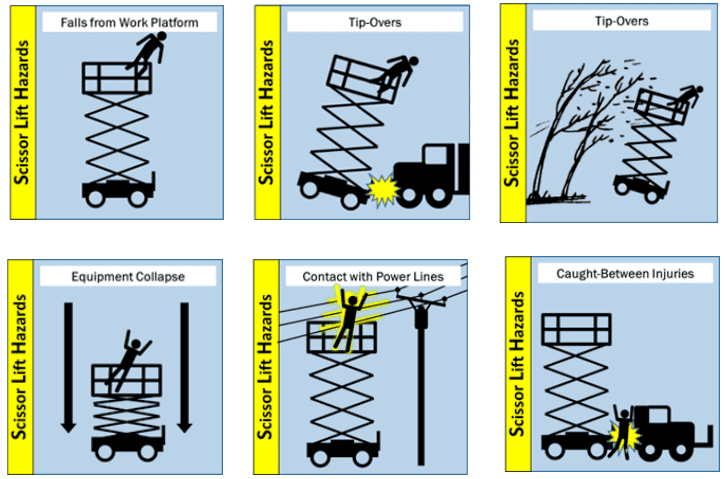

However, there are also certain risks associated with transporting scissor lifts. Due to the narrow passages and densely populated areas that scissor lifts need to pass through during transportation, and the fact that operators generally need to stand and walk for long periods, safe transportation is particularly important.

If a safety accident occurs during transportation, it will not only cause harm to operators but also affect the production progress and economic benefits of the enterprise. The necessity of safe transportation also needs to be highly valued. Only by ensuring the safe transportation of scissor lifts can they better leverage their advantages in logistics transportation and make greater contributions to the development of enterprises.

Preparation before transportation

Equipment inspection

Before transporting the scissor lift, a comprehensive inspection of the equipment must be carried out. Firstly, check the brake system to ensure its good performance and the ability to stop promptly when needed. According to statistics, about 30% of scissor lift accidents are caused by brake failures. Therefore, the importance of checking the brake system is self-evident.

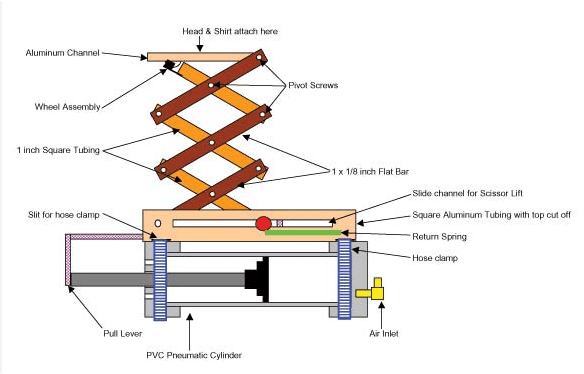

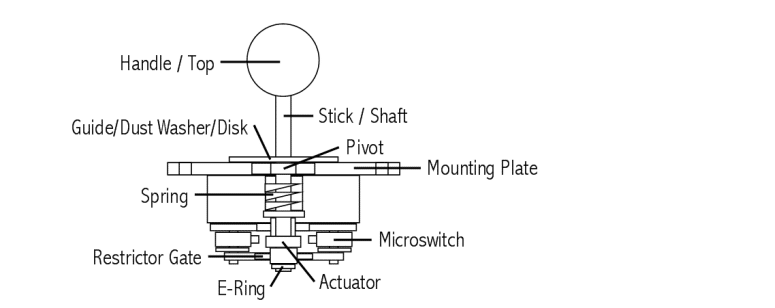

At the same time, it is necessary to check the wear of the tires to ensure that they are not excessively worn or damaged. If there is a problem with the tires, it may cause the scissor lift to become unstable during driving, increasing the risk of accidents. In addition, it is necessary to check other components of the scissor lift, such as the hinge system, push rod connection, and operating lever, to ensure that they are all in good working condition. Transportation can only proceed after confirming that all components of the scissor lift are functioning properly.

Road cleaning

Before transporting scissor lifts, obstacles on the road surface must be cleared to ensure a flat surface. This is because the scissor lift needs to maintain stability during driving, and if there are obstacles on the road, it may cause the scissor lift to lose control. For example, if there is a large stone on the road surface, the scissor lift may collide with it while driving, causing the vehicle to lose balance or even overturn.

Therefore, before transporting the scissor lift, it is necessary to carefully inspect the road surface and remove all obstacles. At the same time, it is necessary to ensure that the road surface is flat, without potholes or bumps. If the road surface is uneven, the scissor lift may experience bumps during operation, which can affect the stability of the cargo and increase the risk of accidents. In short, clearing obstacles on the road surface and ensuring a flat road surface are important prerequisites for ensuring the safe transportation of scissor lifts.

Key points during transportation

Stable driving

Stable driving is important during the transportation of scissor lifts. When moving forward, maintain a stable speed and avoid sharp turns and sudden acceleration. Sharp turns may cause the vehicle to lose balance and increase the risk of rollover. Sudden acceleration may cause the goods to shift and affect the stability of the vehicle. According to relevant data statistics, scissor lift accidents caused by sharp turns and rapid acceleration account for about 20% of transportation accidents.

Never turn the steering wheel when going downhill, as this is to prevent rollover or skidding accidents. When going downhill, the vehicle itself has a certain speed, and if you turn the steering wheel at this time, it is easy for the vehicle to lose control. For example, on a downhill section with a slope of 15 degrees, if the driver turns the steering wheel, the scissor car may slip due to inertia and centrifugal force, and in severe cases may even roll over.

Balance control

Maintaining the balance of the scissor lift at all times is the key to ensuring safe transportation. To achieve this, it is first necessary to pay attention to the distribution of the vehicle’s center of gravity. The center of gravity of the scissor lift should be kept as close to the center of the vehicle as possible to avoid excessive deviation. During the driving process, it is necessary to observe the condition of the vehicle at all times. Once any signs of tilting are found, immediate measures should be taken to adjust.

To prevent tipping or tilting, the driver should maintain the correct posture during operation. Both hands should firmly grip the handlebars to ensure control of the vehicle. At the same time, the driving speed should be adjusted reasonably according to the road conditions and the weight of the goods. If the road surface is uneven or the goods are heavy, the speed should be appropriately reduced to increase the stability of the vehicle.

Load safety

Choosing suitable packaging is crucial when transporting goods using a scissor lift. Appropriate packaging can ensure that the goods are firm and stable, not easily sliding or tilting. For example, some fragile articles can be packed with foam plastics and other cushioning materials to reduce vibration and collision during transportation.

Balancing the loading of goods is also an important aspect of ensuring load safety. For the transportation of multiple goods, attention should be paid to the reasonable allocation of weight, ensuring that the center of gravity does not deviate too much and remains in the center position of the vehicle. According to the actual situation, ropes or straps can be used to fix the goods on the scissor lift to prevent them from shifting during transportation.

During transportation, the condition of the goods should be observed at all times. If the goods are found to be loose or displaced, they should be stopped in a timely manner for adjustment. At the same time, it is necessary to adjust the driving speed reasonably according to the nature and weight of the goods, in order to avoid the goods falling or the vehicle losing balance due to excessive speed.

Safety requirements and measures

Personnel safety

When using a scissor lift for transportation, operators must wear appropriate work clothes, including protective shoes, knee pads, gloves, etc., to protect their bodies and hands and feet. Protective shoes can effectively prevent feet from being injured by heavy objects or crushed by vehicles. According to statistics, foot injury accidents caused by not wearing protective shoes account for a relatively high proportion in the logistics transportation industry.

Kneepads can protect the knees during operation, reducing injuries caused by prolonged standing or accidental collisions. Gloves can provide protection for the hands, preventing them from being scratched by sharp objects or worn during the handling of goods. In short, wearing appropriate work clothes is an important measure to ensure the personal safety of operators.

Set up protection

It is crucial to set up protective railings and signs around the scissor lift, maintain a safe distance, and prevent pedestrians from entering the transportation area. Protective railings can effectively prevent pedestrians from approaching a moving scissor lift and prevent accidents from occurring. At the same time, setting clear signs such as “Danger Zone, Do Not Approach” can remind pedestrians to pay attention to safety.

Generally speaking, the height of protective railings should not be less than 1.2 meters to ensure effective obstruction of pedestrians. In addition, a reasonable safety distance should be set according to the actual situation, and it is generally recommended to maintain a safety distance of at least 2 meters. This can provide pedestrians with sufficient reaction time and safe haven space in case of accidents with scissor lifts.

Fixed parking

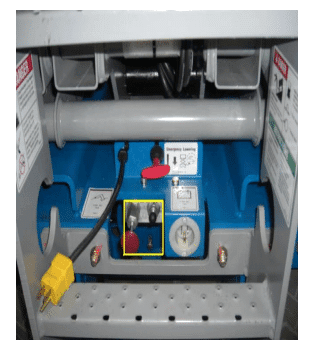

When parking, the scissor lift should be fixed in place to prevent accidents during transportation and ensure the safety of the workplace. Specialized fixing devices such as brake locks, wheel stops, etc. can be used to securely fix the scissor lift to the ground. The brake lock can prevent the scissor car from sliding when parked, while the wheel stopper can prevent the wheels from rolling.

When fixing the scissor lift, ensure that the fixing device is firmly installed and will not loosen or fall off. At the same time, when parking, choose a stable and hard ground to avoid parking the scissor lift on slopes or uneven surfaces. In addition, the power supply of the scissor lift should be turned off promptly after parking to prevent accidental operation from causing the vehicle to start.

Other precautions

Cleaning and maintenance

Keeping the scissor lift clean is an important step in ensuring its safe operation. During the use of the scissor lift, dust and debris are prone to accumulate on the wheels and control lever, which can affect the operation of the scissor lift and even cause safety accidents. For example, if too much debris accumulates on the wheels, it may cause the wheels to slip and affect the vehicle’s driving stability.

The debris on the joystick may affect the operator’s control accuracy of the vehicle. Therefore, during the use and storage of scissor lifts, it is necessary to regularly clean and maintain them, especially key parts such as wheels and control levers.

Mark warning

Before using the scissor lift, it is necessary to notify other workers in the construction area and set up signs and warnings on the construction site. This can effectively prevent personnel from approaching or crossing the scissor lift operation area, reducing the occurrence of safety accidents.

Transporting personnel on scissor lifts is a very dangerous behavior, which can easily lead to safety accidents such as falls. Setting up obvious signs and warnings, such as placing warning signs, setting up warning lines, etc., can remind surrounding personnel to pay attention to safety and maintain a safe distance.

Control load

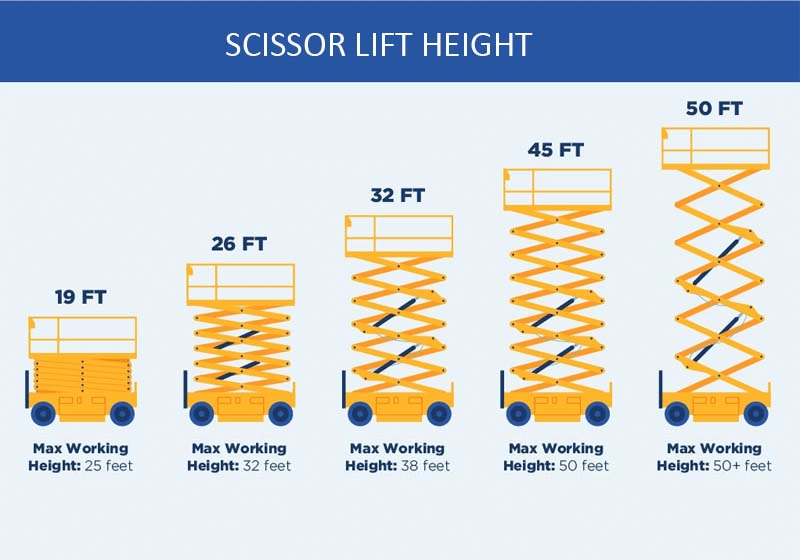

Strictly controlling the load capacity is the key to ensuring the safe transportation of scissor lifts. When using a scissor lift for transportation, the load capacity must be strictly controlled and must not exceed the maximum load of the scissor lift. According to relevant data statistics, excessive load is one of the main reasons for scissor lift overturning, accounting for about 30% of scissor lift accidents. Overloading not only causes injury to operators, but may also damage the transported goods.

Therefore, before using a scissor lift, it is necessary to understand its maximum load capacity and arrange the handling tasks reasonably according to the actual situation.

Training and Operation

Operators need to receive professional training and be familiar with the performance, operation methods, and safety precautions of scissor lifts. Only personnel who have received training and obtained operation certificates can independently operate the scissor lift to avoid safety accidents caused by misoperation.

When operating the scissor lift, it is necessary to strictly follow the operating instructions and not make arbitrary changes or overload operations. At the same time, operators should remain standing while operating the scissor lift, loose clothing and hair should be secured, and attention should be maintained at all times. If high load operations are required, operators need to have a thorough understanding of the job content and possess high technical skills.

Regular inspection

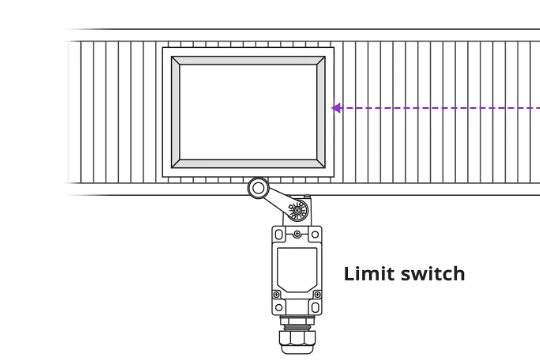

Regular inspection and maintenance of scissor lifts are important measures to ensure their safe operation. During use, the core components of the scissor lift, such as driving wheels, lifting equipment, working functions, safety protection devices, etc., may malfunction due to wear and aging.

Therefore, these components should be inspected and maintained regularly, and the instructions in the user manual should be followed. If there is a malfunction, it needs to be repaired and replaced immediately. For example, wear and tear on the driving wheels may affect the stability of the scissor lift, malfunction of lifting equipment may cause cargo to fall, and damage to safety protection equipment may reduce the safety of operators. Regular inspection and maintenance can timely detect and solve these problems, ensuring the good working condition of the scissor lift.