How To Operate The Scissor Lift?

The Scissor Lifts

The self-propelled scissor lift is a mechanical equipment used for high-altitude operations, which can perform safe and efficient operations indoors and outdoors. To ensure the safety of operators and the smooth progress of operations, this article has formulated corresponding operating procedures.

Related Reading:

How To Operate A Boom Lift?

Preparation before use

Check the working status of the platform, including checking the circuit, hydraulic oil, and lubrication conditions, to ensure that the platform is in good working condition.

Check the surrounding environment to ensure that there are no obstacles around the platform, and choose a suitable location to place the platform according to the work needs.

Adjust the height and angle of the platform according to the homework needs, and check if all control equipment is working properly.

Notes on work

Operators must wear personal protective equipment such as helmets and work clothes, and fasten safety belts on the platform to ensure their safety.

Operators must be familiar with and comply with the platform’s user manual and relevant safety regulations and are not allowed to operate without authorization.

Overloading is not allowed on the platform, and walking, playing, and other behaviors are prohibited on the platform.

During the homework process, it is necessary to always pay attention to the surrounding environment, especially weather conditions such as high-altitude wind, to ensure work safety.

After the homework is completed, it is necessary to clean up the debris on the platform promptly and put the platform back in place.

Key points of operation

On/off operation: Turn the limited switch lever from the “OFF” position to the “ON” position to start the platform. Attention: The platform should undergo multiple trial runs before entering working mode.

Mobile operation: Control the platform’s movement by manipulating the platform’s direction through the handle. Attention: The platform should remain stable during movement to avoid collisions and friction.

Lifting operation: Control the lifting of the platform by controlling the lifting rod on the platform. Attention: During the lifting process, the platform should be stable and not too hasty.

Tilt operation: Control the tilt angle of the platform by controlling the tilt lever on the platform. Attention: The platform should be stable during the tilting process to avoid tipping over.

Summary

The operating procedures of the self-propelled scissor lift are an important guarantee for ensuring the safety and efficiency of operators to complete the work. Before carrying out high-altitude operations, operators must conduct sufficient inspection, preparation, and training on the platform, master the key points of operation, and always maintain attention and vigilance to ensure safe and efficient completion of the operation.

Dangerous

Dangerous

Before operating or repairing the machine, you should read, understand, and comply with these safety rules and operating and maintenance instructions. Only well-trained and authorized personnel are allowed to operate or repair the machine. The manual should be considered as a part of the machine and always kept with the machine. If you have any questions, please contact our company.

Failure to comply with the instructions and safety rules in this manual will result in death or serious injury incidents.

Do not operate unless:

- You have understood and practiced the rules for the safe operation of the machine in this user manual.

- Avoid dangerous situations: Know and understand the above rules before continuing to the next step

- Always perform pre-operation checks.

- Always perform pre-use functional testing.

- Inspect the workplace.

- Only use the machine according to its design intent.

- Should read, understand, and comply with the manufacturer’s instructions and safety rules, Safety and operational safety rules and maintenance safety

- Rules and machine labeling.

- Users should read, understand, and comply with safety rules and workplace regulations.

- Must read, understand, and comply with all government regulations used.

- You have received appropriate training on safe operation of the machine.

Do not use this machine for welding ground wires, unless the machine is equipped with welding wire options to the platform and the connection method is correct.

The danger of tipping over

The personnel, equipment, and materials on the platform shall not exceed the maximum carrying capacity of the platform or the maximum lifting weight of the extended part of the platform.

Max Loading Capacity: TCPT0808HD/TCPT1008HD/TCPT1212HD/TCPT1412HD/TCPT1612HD

| Platform retraction(06) | TCPT0808HD | 320KG | |

| Platform retraction(08) | TCPT1008HD | 320KG | |

| Platform retraction(10) | TCPT1212HD | 320KG | |

| Platform retraction(12) | TCPT1412HD | 320KG | |

| Platform retraction(14) | TCPT1612HD | 230KG | |

Max Occupant in standard ANSI & CE: 2

Max Occupant-standard ANSI & CE

- Outdoor working: 1

- Indoor Working: 2

TCPT0808HD/TCPT1008HD/TCPT1212HD/TCPT1412HD/TCPT1612HD

The platform can only be lifted and lowered when the machine is on a sturdy and flat ground.

Do not use the tilt alarm as a horizontal indicator. The tilt alarm on the chassis only sounds when the machine tilts.

If the tilt alarm sounds:

Reduce the platform. Place the machine on a sturdy and level ground. If a tilt alarm sounds when lifting the platform, lower the platform very carefully.

Do not change or damage the limit switch.

When the platform is raised, the driving speed must not exceed 0.8 kilometers per hour.

Do not operate the machine during strong or gusty winds. Do not increase the surface area or load of the platform. Increasing the area exposed to the wind will reduce the stability of the machine.

When the platform is raised, the machine cannot travel on uneven terrain, unstable surfaces, or other dangerous conditions, or in the vicinity of these areas.

When the machine is in a retracted state, extreme caution should be taken and the speed should be reduced when driving on uneven terrain, gravel, unstable or smooth surfaces, near openings and steep slopes.

Operation Introduction of the Scissor Lifts

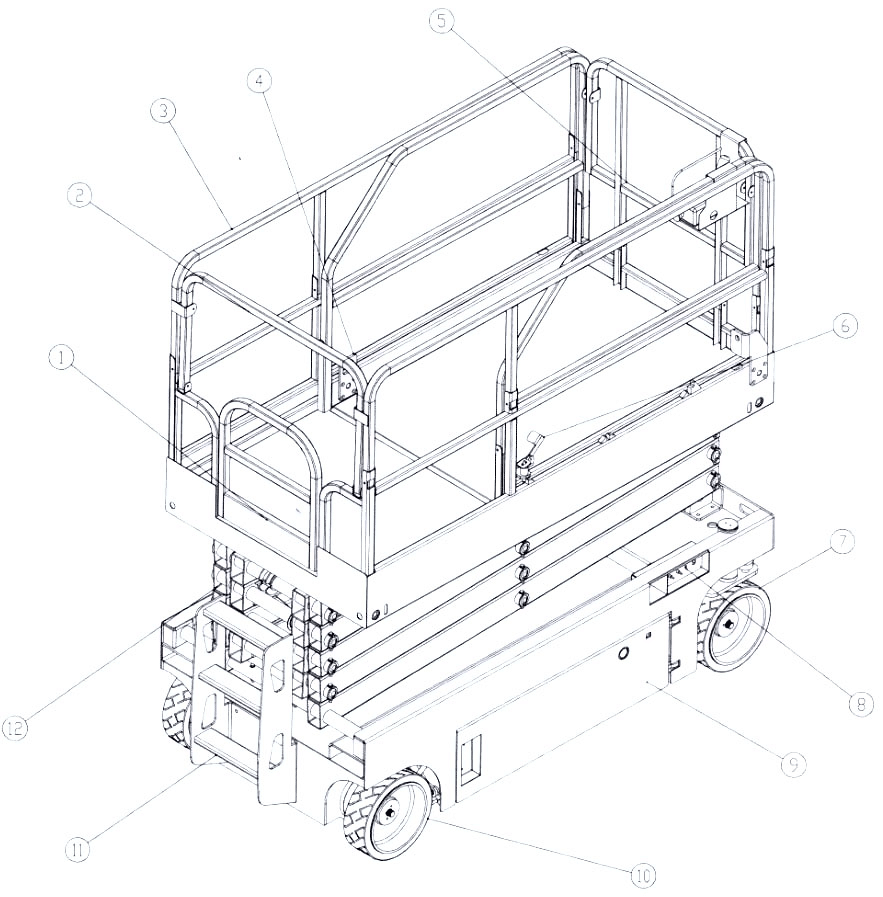

Component Introduction

- Platform Entrance Door

- Platform Entrance Bar

- Platform Protective Fence

- Tether Fixation Point

- Platform Extension

- Platform Extension Release Pedal

- Turning Tires

- Ground Operation Panel

- Power Unit Box

- Fixed Brake Wheel

- Entrance Staircase

- Arm Frame